A professional tool maintenance service ensures your tools are kept in optimal condition and ready for use. When it comes to maintaining your tools, a professional service can provide a range of benefits.

These include regular inspections to identify any potential issues, prompt repairs to prevent further damage, and proper cleaning and lubrication to enhance performance. Additionally, a professional service can offer expert advice on tool care and maintenance, helping you extend the lifespan of your equipment and avoid costly replacements.

By investing in a professional tool maintenance service, you can expect efficient and reliable tools that enable you to work smoothly and effectively.

Understanding The Importance Of Professional Tool Maintenance

Regular professional tool maintenance is essential for ensuring the longevity and performance of your tools. A reliable service will provide thorough inspections, repairs, and cleaning to keep your tools in optimal condition, minimizing downtime and maximizing productivity.

Regular maintenance is crucial for tools to ensure their optimal performance and longevity. Hiring a professional tool maintenance service can provide numerous benefits and maximize the lifespan of your tools. This section will explore why regular maintenance is important, the benefits of hiring a professional service, and the significance of maximizing tool lifespan.

Why Regular Maintenance Is Crucial For Tools

- Prevents breakdowns: Regular maintenance helps identify and address any potential issues with your tools before they escalate into major breakdowns, reducing costly repairs and downtime.

- Ensures safety: By keeping your tools properly maintained, you minimize the risk of accidents or injuries caused by faulty equipment or malfunctioning parts.

- Enhances efficiency: Well-maintained tools operate at their optimal level, ensuring smooth performance and efficient productivity.

- Preserves functionality: Over time, tools can experience wear and tear. Regular maintenance helps to restore and preserve their functionality, avoiding performance degradation.

- Saves money in the long run: While professional tool maintenance may involve upfront costs, it can save you money in the long run by preventing major repairs or early replacements.

Benefits Of Hiring A Professional Tool Maintenance Service

- Expert knowledge and skill: Professional tool maintenance services have trained technicians with extensive knowledge and experience in handling various tools. They possess the expertise to diagnose and fix issues effectively.

- Access to specialized tools and equipment: Professional services have access to specialized tools and equipment required for thorough cleaning, calibration, and repairs. This ensures the highest level of maintenance for your tools.

- Regular servicing schedules: By hiring professionals, you can establish a regular servicing schedule tailored to your specific needs. This proactive approach helps to maintain your tools in top condition and minimize unexpected failures or breakdowns.

- Manufacturer’s recommendations followed: Professional services are well-versed in the manufacturer’s guidelines regarding tool maintenance. They adhere to these recommendations, ensuring that your tools receive the care they need to perform optimally.

- Time-saving: Outsourcing tool maintenance to professionals frees up your time to focus on core activities, increasing productivity and efficiency for your business.

Significance Of Maximizing Tool Lifespan

- Cost-effectiveness: Maximizing the lifespan of your tools means getting the most out of your investment. By prolonging their usability, you reduce the frequency of replacements, ultimately saving money in the long term.

- Increased reliability: When tools are well-maintained and last longer, you can rely on them to consistently deliver high-quality results, minimizing disruptions to your work.

- Sustainability: Extending the lifespan of your tools contributes to a more sustainable approach as it reduces waste from premature disposal and lowers the demand for new tools.

- Reputation and customer satisfaction: By using well-maintained tools, you can provide reliable and efficient services to your customers, enhancing your reputation and ensuring their satisfaction.

By understanding the importance of professional tool maintenance, you can make informed decisions regarding the care of your tools. Hiring a professional tool maintenance service offers numerous benefits, including expert knowledge, access to specialized tools, and customized servicing schedules. Maximizing tool lifespan not only saves costs but also improves reliability, promotes sustainability, and enhances your reputation in delivering reliable services.

What To Look For In A Professional Tool Maintenance Service

Looking for a professional tool maintenance service? Make sure they offer comprehensive services, timely repairs, quality workmanship, and affordable pricing. Trustworthy technicians with expertise in handling a wide range of tools are essential for reliable service.

When it comes to entrusting your valuable tools to a professional maintenance service, it’s crucial to select one that meets your expectations and ensures your tools receive the best care. To help you make an informed decision, here are some key factors to consider:

Qualifications And Certifications Of The Technicians

- Experienced technicians: Look for a service provider with technicians who have extensive experience in tool maintenance. Experienced technicians will have encountered a wide range of tool issues and can efficiently diagnose and repair them.

- Specialized certifications: Professional certifications demonstrate that technicians have undergone rigorous training and possess the necessary skills to handle various types of tools. Look for certifications such as Certified Equipment Specialist (CES) or Certified Tool Technician to ensure expertise in the field.

- Ongoing training and learning: Maintenance service providers that prioritize ongoing training for their technicians stay up-to-date with the latest advancements in tools and equipment. This ensures that the technicians are knowledgeable about new models and can provide effective maintenance and repairs.

Range Of Services Offered

- Comprehensive repairs: A reputable maintenance service should offer a wide range of repair services, from simple repairs to complex overhauls. This ensures that all your tool maintenance needs can be met under one roof, saving you time and effort.

- Preventive maintenance: Look for a service provider that not only offers repairs but also emphasizes preventive maintenance. Regular maintenance can help identify potential issues before they become major problems, extending the lifespan of your tools and reducing downtime.

- Calibration services: If your tools require precise measurements, ensure that the maintenance service provides calibration services. Properly calibrated tools ensure accurate results, enhancing your work quality and productivity.

Reputation And Customer Reviews

- Positive customer reviews: Check online platforms, such as review websites or social media, to gauge the reputation of the maintenance service. Positive reviews from satisfied customers are a good indicator of the service provider’s reliability and quality of work.

- Referrals and recommendations: Seek recommendations from colleagues, friends, or other professionals who have used tool maintenance services before. Their firsthand experiences can provide valuable insight into the service provider’s reputation.

- Established reputation in the industry: A maintenance service with a long-standing reputation in the industry is likely to have a track record of consistently delivering high-quality services. Look for established service providers that have built trust over time.

Remember to consider these factors when choosing a professional tool maintenance service provider. Qualifications and certifications of the technicians, the range of services offered, and the service provider’s reputation and customer reviews are all essential in ensuring you receive reliable and efficient maintenance for your valuable tools.

Key Services Offered By Professional Tool Maintenance Companies

Professional tool maintenance companies offer a range of key services to ensure your tools are in optimal condition. From regular cleaning and lubrication to repair and calibration, you can expect thorough and professional maintenance for your tools.

When it comes to maintaining your tools and equipment, it’s essential to rely on the expertise of professional tool maintenance companies. These specialists are equipped with the knowledge and skills to ensure that your tools are in optimal condition, improving their performance and longevity.

Here are some key services you can expect from a reputable tool maintenance provider:

Cleaning And Lubricating Tools:

- Thoroughly clean all tools to remove dirt, grime, and debris that can affect their functionality.

- Utilize appropriate cleaning solutions and techniques to avoid any damage.

- Inspect and lubricate moving parts to reduce friction and enhance performance.

- Apply corrosion-resistant coatings to prevent rust and prolong the lifespan of the tools.

Repairing And Replacing Damaged Parts:

- Identify and assess any damaged or worn-out components in your tools.

- Provide professional repair services to restore functionality and safety.

- Replace irreparable parts with high-quality replacements to ensure optimum performance.

- Utilize genuine manufacturer parts to maintain compatibility and preserve the tool’s integrity.

Sharpening And Maintaining Cutting Edges:

- Assess the sharpness and condition of cutting edges, such as blades and bits.

- Utilize specialized sharpening techniques to restore the original sharpness.

- Ensure proper alignment of cutting edges for precise and efficient cutting.

- Regularly maintain and touch up cutting edges to prolong their lifespan.

By opting for professional tool maintenance services, you can rest assured that your tools are in the hands of experts dedicated to enhancing their performance and longevity. From thorough cleaning and lubrication to repairing damaged parts and maintaining cutting edges, these services will help you make the most of your valuable tools.

Entrust your equipment to professionals and enjoy the benefits of well-maintained tools that provide optimal results for your projects.

Cleaning And Lubricating Tools

A professional tool maintenance service ensures that your tools are thoroughly cleaned and properly lubricated, allowing them to function at their best. Expect experienced technicians, efficient cleaning processes, and the use of high-quality lubricants to prolong the lifespan of your tools.

Importance Of Cleaning Tools Regularly

Regular cleaning of tools is essential to maintain their performance and longevity. Here are several reasons why cleaning tools regularly is important:

- Preventing rust and corrosion: Cleaning tools helps remove dirt, moisture, and other contaminants that can lead to rust and corrosion, which can degrade the quality and functionality of the tools.

- Enhancing safety: Clean tools reduce the risk of accidents and injuries. Accumulated debris, such as dust or grime, can interfere with proper tool operation, leading to mishaps. Cleaning ensures that tools are in good working condition, minimizing potential hazards.

- Extending tool lifespan: Routine cleaning helps prolong the lifespan of tools. Removing dirt and debris prevents wear and tear, allowing tools to function optimally for a longer period. As a result, you can save money on replacements or repairs.

- Maintaining performance: Clean tools perform better. Removing built-up residues, such as grease or oil, ensures smooth operation and precision. This is especially important for tools that require precise measurements, such as calipers or measuring tapes.

Types Of Cleaning Methods Used

When it comes to tool maintenance, professionals use various cleaning methods depending on the tool’s type and condition. Here are common techniques employed:

- Wiping and brushing: This method involves using cloths, brushes, or air compressors to remove loose debris and dust from tool surfaces. It is suitable for tools that are not heavily soiled.

- Solvent cleaning: Professionals may use solvents or degreasers to dissolve oil, grease, or other stubborn substances. This method is effective in removing heavy build-up, but caution is necessary to avoid damaging sensitive tool components.

- Ultrasonic cleaning: Ultrasonic cleaners use high-frequency sound waves to create tiny bubbles that help remove contaminants from tools. This method is gentle yet highly effective for cleaning intricate or delicate tools.

Proper Lubrication Techniques

Lubrication is an essential part of tool maintenance, as it helps reduce friction, prevent rust, and ensure smooth operation. Consider the following proper lubrication techniques:

- Choosing the right lubricant: Different tools require specific lubricants depending on their materials and purposes. Research the manufacturer’s recommendations or consult professionals to select the appropriate lubricant.

- Applying lubricant correctly: Apply lubricant sparingly and precisely to the designated areas of the tool. Excessive lubrication can attract dirt and cause unnecessary mess. Follow the manufacturer’s instructions for the best results.

- Regular reapplication: Lubricants can dissipate over time or with prolonged tool use. To maintain optimal lubrication, consider establishing a regular schedule for reapplying lubricants to your tools.

Remember, proper cleaning and lubrication techniques can significantly extend the lifespan, enhance performance, and ensure the safety of your tools. Incorporating regular maintenance into your tool management routine will pay off in the long run.

Repairing And Replacing Damaged Parts

Professional tool maintenance services ensure that you can expect efficient and reliable repairs and replacements of damaged parts. With their expertise and attention to detail, you can trust that your tools will be restored to their optimal working condition.

When it comes to professional tool maintenance services, one of the key aspects is repairing and replacing damaged parts. Over time, tools can suffer various types of damage due to wear and tear or accidents. To ensure the efficient functioning of your tools, it is crucial to address these damages promptly and effectively.

Let’s delve into the common types of tool damage, the processes involved in repairing tools, and the importance of using genuine replacement parts.

Common Types Of Tool Damage

Tools can experience different types of damage depending on their specific functions and usage. Some common types of tool damage include:

- Cracked or broken handles: Tools with handles, such as hammers or wrenches, are prone to cracks or breaks. This can compromise their usability and overall safety.

- Worn-out blades or bits: Tools like saws, drills, or grinding equipment often face blade or bit wear, leading to reduced efficiency and precision.

- Corroded or rusted surfaces: Moisture or exposure to harsh environments can cause corrosion or rust on tool surfaces, hindering their performance and potentially leading to further damage.

- Faulty electrical components: Power tools may suffer from issues like faulty switches, wiring problems, or malfunctioning motors, affecting their functionality and safety.

- Loose or missing parts: Sometimes, tools may have loose or missing components, such as screws, nuts, or bolts, which need to be addressed to ensure proper operation.

Processes Involved In Repairing Tools

Repairing damaged tools is a meticulous process that involves several steps, ensuring that the tools regain their functionality and reliability. The typical processes in repairing tools include:

- Assessment and evaluation: A skilled technician assesses the extent of the damage and evaluates the reparability of the tool. They identify the specific parts that need repair or replacement.

- Disassembly: If necessary, the tool is disassembled to access the damaged components more effectively. This aids in thorough inspection and enables focused repairs.

- Cleaning and refurbishment: The damaged parts are cleaned and refurbished to remove any dirt, rust, or corrosion. This helps restore the tool’s appearance and functionality.

- Repair or replacement: Depending on the damage, the technician either repairs the damaged part or replaces it with a new one. Genuine replacement parts are often preferred to ensure optimal performance.

- Reassembly and testing: After the necessary repairs or replacements, the tool is reassembled and thoroughly tested to ensure that it functions as expected. This step verifies the effectiveness of the repairs and guarantees the tool’s safety.

Importance Of Using Genuine Replacement Parts

When it comes to repairing tools, using genuine replacement parts is essential for several reasons:

- Quality assurance: Genuine replacement parts are designed and produced to the manufacturer’s standards, ensuring compatibility, reliability, and optimal performance.

- Longevity and durability: Genuine parts are made from high-quality materials, providing better longevity and durability compared to generic or aftermarket alternatives.

- Safety and compatibility: Genuine replacement parts are tested and approved to work seamlessly with the specific tool, ensuring safety and avoiding potential risks associated with ill-fitting or subpar parts.

- Preserving warranty: Using genuine replacement parts typically preserves the warranty of the tool, offering assurance and support from the manufacturer.

- Maintaining tool value: Repairing tools with genuine replacement parts helps maintain their value, as using substandard parts could diminish their performance and resale potential.

A professional tool maintenance service encompasses repairing and replacing damaged parts to ensure the continued efficiency and safety of your tools. By addressing common types of tool damage, following meticulous repair processes, and utilizing genuine replacement parts, you can extend the lifespan of your tools and maintain their optimal performance.

Sharpening And Maintaining Cutting Edges

A professional tool maintenance service provides expert care for your cutting edges, ensuring they are always sharp and in top condition. With their expertise, you can expect precision, reliability, and prolonged tool lifespan. Leave the sharpening and maintenance to the professionals for optimal results.

Why Sharp Cutting Edges Are Crucial:

- Sharp cutting edges are essential for achieving clean and precise cuts, regardless of the tool type. Dull edges can lead to jagged, uneven cuts that compromise the quality of the work.

- Sharp edges also ensure the efficient use of tools as they require less force and effort to achieve desired results. This not only increases productivity but also reduces the risk of fatigue and injury for the user.

- Maintaining sharp cutting edges is crucial for extending the overall lifespan of tools, as it minimizes wear and tear on the tool itself. This translates into cost savings in the long run, as tools don’t need to be replaced as frequently.

Techniques Used To Sharpen Tools:

- Grinding: Using abrasive surfaces, such as grinding wheels or belts, to remove material and restore the cutting edge’s sharpness.

- Honing: The process of refining the edge by using fine abrasives in a controlled manner. This technique is especially effective for maintaining the sharpness of delicate or precision tools, like knives and chisels.

- Sharpening stones: Natural or synthetic stones with varying degrees of coarseness used to sharpen and shape cutting edges through manual manipulation.

- Tungsten or diamond sharpeners: These tools use tungsten carbide or diamond-coated surfaces to remove material from the blade, effectively sharpening it with minimal effort.

- Whetstones: Natural or synthetic stones, usually accompanied by lubricating fluids, that offer a versatile and effective approach to sharpening a wide range of tools.

Tips For Maintaining Cutting Edges Between Professional Maintenance:

- Regular cleaning: Remove any debris or gunk from the cutting edges after each use. This prevents buildup, which can impede the sharpness and performance of the tool.

- Proper storage: Store tools in a clean, dry area to avoid exposure to moisture or humidity that could cause corrosion or dullness.

- Lubrication: Apply a thin layer of oil or lubricant to the cutting edges, especially for tools like pruning shears or hand saws, to minimize friction and keep them operating smoothly.

- Controlled usage: Avoid using tools for tasks beyond their intended purpose, as this can lead to premature dulling or damage. Using the right tool for the job ensures optimal performance and longevity of cutting edges.

- Periodic inspection: Regularly examine the cutting edges for signs of wear, damage, or dullness. Address any issues promptly to prevent further deterioration and ensure the tools perform at their best.

Remember, keeping your tools’ cutting edges sharp and well-maintained is crucial for achieving optimal performance, efficiency, and safety. By following these tips and relying on professional maintenance services when needed, you can ensure your tools remain in top shape for a longer lifespan and better results.

Costs And Timelines For Professional Tool Maintenance

Discover what to expect from a professional tool maintenance service, including insights on costs and timelines. Keep your tools running smoothly without any delays or unexpected expenses.

Whether you own a few tools or operate a large workshop, regular maintenance is essential to ensure the longevity and optimal performance of your equipment. Professional tool maintenance services can help you keep your tools in top shape, saving you time, money, and potential headaches.

But what can you expect in terms of costs and timelines for these services? Let’s explore the factors that influence the cost of maintenance, the average turnaround time, and considerations for budgeting and scheduling.

Factors Influencing The Cost Of Maintenance:

- Tool complexity: The complexity of the tool and its components can impact the cost of maintenance. More intricate tools may require specialized skills, resulting in higher service fees.

- Parts replacement: If your tools require replacement parts during the maintenance process, this can add to the overall cost. The availability and cost of these parts may vary depending on the tool brand and model.

- Severity of damage: The extent of damage or wear and tear on your tools can influence the cost. Minor repairs or routine maintenance may be less expensive compared to extensive repairs or significant damage.

- Service provider expertise: The experience and reputation of the maintenance service provider can also affect the cost. Established professionals with a proven track record may command higher prices for their expertise.

Average Turnaround Time For Tool Maintenance:

- Simple maintenance tasks: Routine maintenance tasks, such as basic cleaning, lubrication, and adjustments, can often be completed within a few hours to a day.

- Minor repairs: If your tools require minor repairs, the average turnaround time can range from a day to a few days. It may depend on the volume of repairs in the service provider’s queue.

- Extensive repairs or complex tasks: For more complex maintenance or repairs, the turnaround time may vary. It could take several days to a week or longer, depending on the nature of the repairs, availability of parts, and the workload of the service provider.

Considerations For Budgeting And Scheduling:

- Assess the frequency of maintenance: Consider how often your tools require maintenance to establish a budget. Some tools may need more frequent attention than others, so it’s essential to factor in these recurring costs.

- Determine the importance of quick turnaround: If downtime of your tools is a critical concern, you may need to prioritize service providers with shorter turnaround times, even if it means potentially paying a higher price for expedited services.

- Seek multiple quotes: To ensure you’re getting a fair price for your tool maintenance, consider obtaining quotes from multiple service providers. This allows you to compare costs, turnaround times, and quality of service to make an informed decision.

The cost and timeline for professional tool maintenance services can vary depending on factors such as tool complexity, parts replacement, severity of damage, and service provider expertise. Understanding these factors and considering your budget and scheduling needs will help you make informed decisions when selecting a professional maintenance service.

Tips For Maximizing Tool Performance Between Maintenance Services

Get the most out of your tools with these valuable tips to maximize performance between maintenance services. Discover what to expect from a professional tool maintenance service and ensure your tools are always in top shape for optimal functionality.

Proper Storage And Handling Practices:

- Keep your tools in a clean and dry environment to prevent rust and damage.

- Store them in a designated tool box or cabinet to protect them from dust and debris.

- Use proper tool organizers or trays to keep them organized and easily accessible.

- Avoid tossing or dropping tools, as this can cause unnecessary wear and tear.

- Handle tools with care and avoid excessive force or pressure when using them.

Regular Cleaning And Inspection:

- Clean your tools after use to remove dirt, grease, and other contaminants.

- Use appropriate cleaning products and tools to ensure thorough cleaning.

- Inspect your tools for any signs of damage, such as cracks, loose parts, or dull blades.

- Lubricate moving parts if necessary to maintain smooth operation.

- Regularly check electrical cords for any fraying or damage and replace if needed.

Using The Tools Correctly And Safely:

- Read and understand the manufacturer’s guidelines and instructions for proper tool usage.

- Use the right tool for the job to avoid unnecessary strain or damage to the tool.

- Ensure tools are properly maintained and in good working condition before each use.

- Use protective equipment such as gloves, goggles, and earplugs to prevent injuries.

- Follow proper safety procedures and guidelines, including wearing appropriate clothing and shoes.

Remember, maximizing tool performance between maintenance services requires proper storage and handling practices, regular cleaning and inspection, and using the tools correctly and safely. By following these tips, you can ensure the longevity and efficiency of your tools. Happy tooling!

Frequently Asked Questions About Professional Tool Maintenance Services

A professional tool maintenance service ensures that your tools are properly serviced and maintained to extend their lifespan and optimize performance. From regular cleaning and lubrication to thorough inspections and repairs, you can expect expert care and attention to detail for all your tools.

Do I Need To Get My Tools Professionally Maintained?

- Regular maintenance of tools is crucial for their optimal performance and longevity.

- Professional tool maintenance services can diagnose and address hidden issues that may affect your tools’ functionality.

- By entrusting your tools to professionals, you can ensure that they are properly serviced and ready for use when you need them.

- Professional maintenance can prevent costly breakdowns and repairs, saving you money in the long run.

- Additionally, getting your tools professionally maintained can enhance safety, reducing the risk of accidents or injuries caused by faulty equipment.

How Often Should I Have My Tools Serviced?

- The frequency of tool maintenance depends on several factors, including the type of tool, its usage frequency, and the operating conditions it is subjected to.

- As a general rule of thumb, it is recommended to have your tools serviced at least once a year.

- For heavy-duty tools or those used in demanding environments, more frequent maintenance may be necessary.

- Regular inspections can help identify signs of wear or damage early on, enabling prompt repairs and preventing further issues.

- If you notice any abnormalities, such as decreased performance or unusual noises, it is advisable to have your tools serviced immediately.

Can I Perform Tool Maintenance Myself?

- While some basic maintenance tasks can be performed by individuals with proper knowledge and skills, certain tools require specialized expertise.

- Simple tasks like cleaning, lubricating, and inspecting for visible damage can be handled by users.

- However, for complex repairs or adjustments, it is recommended to rely on professional tool maintenance services.

- Attempting to repair or service tools without the necessary expertise may lead to further damage or void warranties.

- Professional technicians have the experience and tools required to handle intricate repairs, ensuring the proper functioning of your tools.

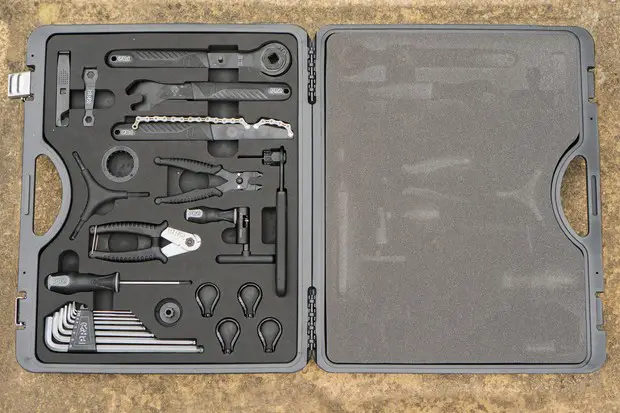

Credit: www.bikeradar.com

Frequently Asked Questions For What Should I Expect From A Professional Tool Maintenance Service?

What Are The Three Most Important Rules Of Tool Maintenance?

The three most important rules of tool maintenance include regular cleaning, proper storage, and routine lubrication.

What Are The General Requirements For Tools And Equipment Maintenance?

To maintain tools and equipment, follow these general requirements: – Perform regular inspections and repairs as needed. – Clean and lubricate moving parts to prevent damage. – Store tools and equipment in a safe and dry place. – Follow manufacturer’s guidelines for maintenance and use.

What Is A Good Maintenance Practice For Tools?

Regular cleaning, lubrication, and storing tools properly enhances their lifespan and performance.

What Are The Benefits Of Having Tool Maintenance?

Tool maintenance has several benefits. It keeps tools functioning optimally, extends their lifespan, and improves safety.

Conclusion

To wrap it up, a professional tool maintenance service is essential for the longevity and optimal performance of your tools. By entrusting experts with the task, you can expect thorough cleaning, inspection, and repairs, ensuring that your tools are always in top condition.

This will not only enhance their efficiency but also contribute to a safer working environment. Moreover, professional maintenance services often offer personalized advice on tool care and usage, helping you to get the most out of your equipment. Additionally, routine maintenance can help you identify potential issues before they turn into costly repairs, ultimately saving you time and money in the long run.

So, don’t overlook the importance of regular tool maintenance and invest in professional services to keep your tools in the best shape possible. Give your tools the care they deserve and enjoy their reliable performance for years to come.