To extend the life of your saw blades, clean them regularly and store them in a dry area. Saw blades are essential tools for woodworking and cutting materials, but they can wear out over time if not properly maintained.

Regular cleaning is crucial in preventing the accumulation of dust, resin, and other debris, which can lead to blade dullness and reduced cutting performance. It is recommended to use a cleaning solvent or a simple mixture of warm water and mild detergent to remove any build-up.

Additionally, ensuring that the blades are stored in a dry area, away from moisture and humidity, will help prevent rust and corrosion. By following these simple steps, you can maximize the lifespan of your saw blades and ensure optimal cutting results for your projects.

Choosing The Right Saw Blade For Longevity

Maximize the lifespan of your saw blades with these tips. Learn how to choose the right blade, maintain it properly, and avoid common mistakes to extend its longevity. Enhance cutting performance and save costs with these expert strategies.

When it comes to extending the life of your saw blades, one of the crucial factors to consider is choosing the right blade for the job. By selecting a saw blade that is specifically designed for the task at hand, you can ensure its longevity and optimize its performance.

Here are some important factors to keep in mind when selecting a saw blade:

- Material: Matching the blade to the material you will be cutting is of utmost importance. Different materials require different types of saw blades to achieve the best results. Ensure that the blade you choose is designed for cutting the specific material you are working with.

- Tooth Count: The number of teeth on a saw blade plays a significant role in its performance and lifespan. Higher tooth count blades are more suitable for making smoother cuts on delicate materials, while lower tooth count blades are better for faster, rougher cuts on tougher materials. Consider the tooth count based on the intended use of the blade.

- Tooth Configuration: Saw blades come in various tooth configurations, each designed for specific applications. Some common tooth shapes include rip, crosscut, and combination teeth. Rip teeth are ideal for cutting along the grain, crosscut teeth for cutting across the grain, and combination teeth for both types of cuts. Make sure to choose the appropriate tooth configuration for your cutting needs.

- Coating: Many saw blades come with special coatings that provide added protection and durability. These coatings can reduce friction, heat buildup, and corrosion, ultimately extending the blade’s lifespan. Look for blades with coatings such as carbide or titanium to enhance performance and longevity.

- Blade Quality: The overall quality of the saw blade significantly affects its longevity. Opt for blades from reputable manufacturers known for producing high-quality tools. Investing in a well-made blade may cost more initially but will prove beneficial in the long run due to its durability.

- Maintenance: Regular maintenance plays a crucial role in extending the lifespan of your saw blades. Keep the blades clean and free from residue, frequently sharpen them or have them professionally sharpened when needed, and store them properly when not in use. Taking proper care of your blades will help maintain their cutting performance and maximize their lifespan.

By considering these factors when selecting a saw blade, you can ensure that your blades have a longer lifespan and consistently deliver excellent results. Remember to choose the blade that matches the material, tooth count, tooth configuration, coating, and overall quality required for your specific cutting needs.

Regular maintenance and proper care will further help in extending the life of your saw blades, ultimately saving you time and money.

Proper Blade Maintenance And Cleaning Techniques

Proper blade maintenance and cleaning techniques are essential for extending the lifespan of your saw blades. By regularly cleaning and sharpening them, you can ensure optimal performance and longevity, saving you both time and money in the long run.

Regular maintenance and proper cleaning techniques are essential to prolong the life of your saw blades and ensure optimal performance. By following these important steps, you can keep your blades in top condition, free from debris and build-up:

Importance Of Regular Cleaning And Inspection

Regular cleaning and inspection of your saw blades are crucial for several reasons. Here’s why you should prioritize this routine maintenance:

- Prevent Build-up: Saw blades can accumulate sawdust, resin, and other debris during use, reducing their cutting efficiency. Regular cleaning helps prevent build-up and maintains the blade’s cutting performance.

- Extend Lifespan: Proper maintenance, such as cleaning and removing rust, can significantly extend the lifespan of your saw blades. Regular inspections also help identify any signs of damage or wear that may require immediate attention.

- Ensure Safety: A clean and well-maintained blade reduces the risk of accidents during cutting tasks. Removing debris and inspecting for damage minimizes the chances of the blade binding or kicking back while in use.

Recommended Cleaning Products And Tools

To effectively clean and maintain your saw blades, consider using the following products and tools:

- Blade Cleaning Solution: Choose a specialized saw blade cleaning solution that is specifically designed to remove pitch, resin, and other contaminants. These solutions are more effective than regular cleaning agents and help restore the blade’s cutting performance.

- Wire Brush: A wire brush with stiff bristles is ideal for removing hardened debris and built-up residue. It can reach into the teeth of the blade, ensuring a thorough cleaning.

- Solvent: A non-flammable solvent, such as denatured alcohol or acetone, can be used to dissolve and remove stubborn resin or gum deposits.

- Soft Cloth or Brush: A soft cloth or brush can be used to wipe away loose debris after cleaning. Make sure to choose a material that won’t scratch or damage the blade’s surface.

Techniques For Removing Sawdust, Resin, And Other Debris

Cleaning your saw blades requires proper techniques to remove sawdust, resin, and other debris effectively. Follow these steps for a thorough cleaning:

- Safety First: Before cleaning, make sure the blade is completely disconnected from the power source and that you are wearing appropriate safety gear, such as gloves and eye protection.

- Soak and Scrub: Submerge the blade in a blade cleaning solution or apply it directly to the blade’s surface. Let it soak for a few minutes to loosen the debris. Then, use a wire brush to scrub away the residue, focusing on the teeth and gullets of the blade.

- Remove Stubborn Residue: For stubborn resin or gum deposits, use a solvent-soaked cloth or brush to dissolve and wipe away the residue. Be cautious when using solvents, as they may have specific safety instructions and precautions.

- Dry and Inspect: After cleaning, thoroughly dry the blade with a clean cloth to prevent any moisture-related issues. Inspect the blade for any signs of damage, such as missing or dull teeth, cracks, or warping. Replace or repair as necessary.

By regularly cleaning and maintaining your saw blades using the proper techniques and tools, you can significantly extend their lifespan, enhance their cutting performance, and ensure a safer working environment.

Tips For Safe And Efficient Blade Usage

Learn how to extend the life of your saw blades with these helpful tips. Discover safe and efficient blade usage techniques to keep your blades sharp and in excellent condition for longer.

Setting The Correct Cutting Parameters:

- Use the right blade for the specific material you are cutting. Matching the correct blade type (i.e., rip-cutting, cross-cutting, or combination) to the material ensures optimal performance and longevity.

- Check the saw’s manufacturer recommendations for the appropriate blade speed and feed rate. Adjusting these parameters correctly will help prevent overheating and premature wear.

- Maintain the right tension in the blade. Too much tension can lead to excessive strain, while too little tension may cause the blade to wander off track.

- Adjust the cutting depth according to the material thickness. Cutting too deep may overload the blade, resulting in damage or breakage.

Proper Sawing Techniques To Minimize Stress On The Blade:

- Start each cut slowly and gradually increase the cutting speed to allow the teeth to properly engage with the material.

- Avoid putting excessive pressure on the blade while cutting. Let the blade do the work, and guide the saw steadily without forcing it.

- Prevent binding by ensuring the material is properly supported and free from obstructions. This reduces strain on the blade and minimizes the risk of kickback.

- Make sure the saw is properly aligned and adjusted. Misalignment can cause the blade to bind, leading to unnecessary stress and potential damage.

Potential Hazards To Look Out For And Avoid:

- Always wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and hearing protection, to guard against potential accidents and injuries.

- Keep the work area clean and clear of debris to prevent obstacles that could interfere with the blade’s performance or cause accidents.

- Beware of hidden nails, screws, or other metal objects that can damage the blade or cause it to deflect. Inspect the material and remove any potential hazards before cutting.

- Be cautious of blade contact with knots or irregular grain patterns in wood. These can cause the blade to bind or kick back, posing a danger to the operator.

Remember, taking proper precautions and adhering to these tips will help extend the life of your saw blades, ensuring safe and efficient cutting operations.

Maximizing Blade Longevity Through Storage And Handling

Extend the lifespan of your saw blades with proper storage and handling techniques. Learn the best practices to maximize blade longevity and save money in the long run.

When it comes to extending the life of your saw blades, proper storage and handling play a crucial role. By creating a suitable storage environment and following a few tips for handling blades, you can prevent damage and ensure blade longevity.

Additionally, knowing how to properly store blades when not in use is essential. In this section, we will explore these aspects in detail.

Creating A Suitable Storage Environment:

- Store blades in a dry and clean area to prevent moisture and corrosion.

- Avoid storing blades near chemicals or harsh solvents that could potentially damage the blade’s coating.

- Keep blades away from extreme temperature changes, as these can cause warping or cracking.

- Use blade storage racks or cases to protect blades from accidental damage and to maintain their shape.

- Consider using blade covers or cases with foam inserts to provide additional cushioning and protection during storage.

Tips For Handling Blades To Prevent Damage:

- Always handle blades with clean, dry hands to prevent the transfer of oil, dirt, or moisture onto the blade surface.

- Use gloves when handling blades to avoid accidental cuts and to protect the blade from oils and acids on your skin.

- When removing or installing a blade, ensure that the saw is powered off and unplugged to prevent accidental injuries.

- Use the appropriate tools, such as blade wrenches, to secure or loosen blades, avoiding excessive force that could damage the blade or saw.

- Avoid dropping or mishandling blades, as this can cause denting, chipping, or misalignment.

How To Properly Store Blades When Not In Use:

- Clean blades thoroughly before storing to remove any debris or residue that could lead to contamination.

- Use blade protectors or covers to shield the blade teeth and prevent them from getting damaged during storage.

- Store blades separately to avoid contact between the teeth, which can result in dulling or chipping.

- Consider labeling or organizing blades based on their size, type, or application for easier retrieval and to prevent accidental mix-ups.

- Store blades in a secure and accessible location to prevent damage from falling or shifting objects.

By following these best practices for storage and handling, you can maximize the lifespan of your saw blades. Taking a little extra care and attention in these areas will not only save you money in the long run but also ensure that your blades perform at their best whenever you need them.

Sharpening And Retoothing Blades For Extended Use

Extend the lifespan of your saw blades with proper sharpening and retoothing techniques. Learn how to maintain and care for your blades for increased durability and efficiency in your cutting tasks.

Identifying Signs Of Blade Dullness And When To Sharpen:

- Blades become dull with repeated use and can be identified through the following signs:

- Frequent snagging or binding of the blade during cuts.

- Burn marks or scorching on the material being cut.

- Reduced cutting speed and precision.

- Difficulty in making smooth and clean cuts.

- When these signs become noticeable, it is time to sharpen the blade to restore its sharpness and cutting efficiency.

Different Methods And Tools For Sharpening Blades:

- There are several methods and tools available for sharpening saw blades, including:

- Manual sharpening using a diamond file or sharpening stone:

- Gently run the file or stone over the teeth of the blade at the correct angle to remove any dullness and restore sharpness.

- Repeat the process for each tooth until the entire blade is sharpened.

- Automatic sharpening using a blade sharpener machine:

- Securely mount the blade in the machine and follow the manufacturer’s instructions for sharpening.

- The machine uses grinding wheels or other abrasive mechanisms to restore the blade’s sharp edge quickly.

- Professional sharpening services:

- Consider sending the blade to a professional sharpening service if you lack the necessary tools or skills.

- These services have specialized equipment and expertise to accurately and effectively sharpen saw blades.

Understanding The Process Of Retoothing And Its Benefits:

- Retoothing refers to the process of replacing damaged or worn-out teeth on a saw blade. It offers the following benefits:

- Restoring full cutting capacity: Retoothing eliminates the need to discard the entire blade when only a few teeth are damaged, extending the overall lifespan.

- Cost-effective solution: Instead of purchasing a new blade, retoothing is a more affordable option that allows you to continue using your existing blade.

- Enhanced cutting performance: By replacing dull or missing teeth, retoothing improves cutting efficiency, resulting in cleaner and smoother cuts.

- Increased operational safety: Retoothed blades reduce the risk of kickbacks and blade binding, ensuring a safer working environment.

Remember, by regularly sharpening your saw blades and considering retoothing when necessary, you can extend their lifespan, save money, and maintain optimal cutting performance.

Upgrading Your Saw Blade: Is It Worth It?

Upgrade your saw blade and extend its lifespan with these tips. Discover how to maximize the performance and durability of your saw blade for efficient cutting.

If you’re an avid woodworker or DIY enthusiast, you know the importance of having a sharp and efficient saw blade. Over time, saw blades can become dull or damaged, leading to less precise cuts and a decrease in productivity. When faced with this dilemma, you may wonder, is it worth upgrading your saw blade?

In this section, we’ll explore some signs that indicate it’s time for an upgrade, considerations to keep in mind when choosing a higher quality blade, and how to weigh the cost-benefit of upgrading versus extending the life of your current blades.

Signs That It’S Time To Upgrade Your Blade:

- Inconsistent or rough cuts: If you notice that your cuts are no longer smooth or accurate, it could be a sign that your saw blade is past its prime. Upgrading to a higher quality blade can significantly improve the precision and overall quality of your cuts.

- Excessive sawdust or burning smell: When your blade is dull or worn, it tends to generate more sawdust than usual and may even produce a burning smell. This indicates that the blade is struggling to cut through the material efficiently, further highlighting the need for an upgrade.

- Increased effort required: If you find yourself exerting more effort or applying more pressure when cutting through materials, it’s a clear indication that your blade needs a replacement. Upgrading to a sharper and more durable blade can make your cutting tasks easier and more efficient.

Considerations When Choosing A Higher Quality Blade:

- Blade material: Different saw blade materials offer varying levels of durability and performance. Consider opting for carbide-tipped blades, as they are known for their hardness and extended lifespan. Diamond-tipped blades are also popular for cutting through harder materials like tiles and masonry.

- Tooth configuration: The tooth configuration of a blade greatly affects its cutting efficiency and the type of material it’s suited for. Different teeth arrangements, such as rip, crosscut, or combination, are designed for specific cutting tasks. Assess your cutting needs and choose a blade with the appropriate tooth configuration.

- Blade size and compatibility: Ensure that the upgraded blade you choose is the correct size and compatible with your saw. Refer to your saw’s manual or consult with a professional to ensure a proper fit and optimal performance.

Weighing The Cost-Benefit Of Upgrading Versus Extending The Life Of Current Blades:

- Cost of upgrading: Upgrading your saw blade may come with an upfront cost, especially if you opt for a higher quality blade. However, it’s essential to consider the long-term benefits that a quality blade can provide, including better performance, extended lifespan, and increased productivity.

- Frequency of use: If you frequently use your saw for various projects, it may be more cost-effective to invest in a higher quality blade that can withstand constant use and deliver consistent results. On the other hand, if your saw sees occasional use, extending the life of your current blades through maintenance and sharpening could be a viable option.

- Project requirements: Evaluating the specific requirements of your projects is crucial when weighing the cost-benefit of upgrading versus extending the life of your saw blades. If you’re working on precision projects or require clean cuts, upgrading to a higher quality blade is likely the better choice. However, for less demanding projects, you may choose to extend the life of your current blades by implementing proper blade care practices.

Remember, upgrading your saw blade is an investment in the quality of your cuts and overall woodworking experience. By recognizing the signs that it’s time for an upgrade, considering essential factors when choosing a higher quality blade, and carefully weighing the cost-benefit, you can make an informed decision that best aligns with your needs and budget.

Troubleshooting Common Saw Blade Issues

Extend the life of your saw blades by troubleshooting common issues. Discover effective strategies to optimize their longevity and maintain their performance.

Identifying and addressing common blade problems:

- Blade Wobbling: A wobbling blade can lead to inaccurate cuts and even be dangerous. Here are some potential causes and solutions:

- Loose Arbor Nut: Tighten the nut using an arbor wrench to ensure a secure fit.

- Blade Misalignment: Adjust the blade so that it sits parallel to the rip fence or miter gauge.

- Bent Blade: Replace the blade if it is visibly bent or damaged.

- Burning: Burning occurs when the saw blade generates excessive heat during the cutting process. Follow these tips to prevent burning:

- Reduce Feed Rate: Slow down the speed at which you push the material through the blade.

- Use a Cooler Blade: Opt for a blade with more teeth or a special coating designed to dissipate heat.

- Check Blade Sharpness: Dull blades tend to generate more heat. Sharpen or replace them as needed.

- Chipping: Chipping is characterized by the splintering or cracking of wood or other materials during cutting. Consider these solutions:

- Blade Quality: Invest in high-quality, carbide-tipped blades that are less prone to chipping.

- Slower Feed Rate: Feed the material through the blade at a slower and more consistent pace.

- Reduce Blade Speed: Adjust the saw’s speed settings to a lower RPM if possible.

Troubleshooting blade binding and kickback situations:

- Blade Binding: Blade binding occurs when the saw blade gets stuck during a cut. To address this issue:

- Ensure Proper Blade Depth: Adjust the blade depth so it protrudes slightly below the material being cut.

- Check for Obstructions: Clear the work area from debris or other potential obstructions.

- Use a Push Stick: Employ a push stick to maintain a safe distance between your hands and the blade while guiding the material.

- Kickback: Kickback refers to the sudden and forceful backward movement of the material, potentially causing injury. Prevent kickback by:

- Installing a Riving Knife: A riving knife helps prevent the material from pinching the back of the blade, reducing the risk of kickback.

- Avoiding Blade Contact with the Workpiece: Be cautious of the blade’s position relative to the material and make sure it doesn’t touch before making the cut.

- Using Rip Fence and Miter Gauge Properly: Position the rip fence and miter gauge securely and follow proper techniques when using them.

By identifying and troubleshooting common blade issues like wobbling, burning, chipping, binding, and kickback, you can extend the life of your saw blades while ensuring safer and more efficient woodworking projects. Remember to address these problems promptly and follow the appropriate solutions to maintain optimal cutting performance.

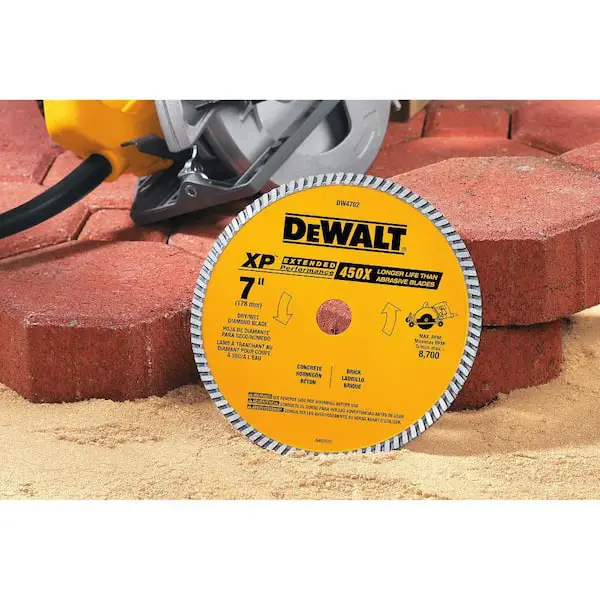

Credit: www.homedepot.com

Proactive Blade Preservation: Preventing Premature Wear

Extend the lifespan of your saw blades with proactive blade preservation techniques. Avoid premature wear by implementing proper maintenance practices and taking steps to minimize damage during use. These measures will help you get the most out of your blades for longer-lasting performance.

A well-maintained saw blade is vital for achieving accurate cuts and ensuring optimal performance. By employing proactive blade preservation techniques, you can extend the life of your saw blades, reducing the need for frequent replacements. In this section, we’ll explore how to properly set up and calibrate your saw equipment, the importance of making accurate cuts to reduce strain on blades, and how implementing preventive maintenance practices can help prolong blade life.

How To Properly Set Up And Calibrate Saw Equipment:

- Ensure the blade is securely attached to the saw, minimizing vibration and preventing premature wear.

- Regularly check and adjust the blade’s alignment to guarantee precise cuts.

- Maintain the appropriate tension in the blade to avoid deflection and blade fatigue.

- Utilize the appropriate hardware and accessories to minimize stress on the blade during operation.

Importance Of Making Accurate Cuts To Reduce Strain On Blades:

- Adhere to cutting guidelines and use appropriate sawing techniques to prevent blade binding and excessive friction.

- Maintain sharpness by using the correct blade for the specific material and type of cut.

- Reduce the feed rate to prevent overheating and excessive wear.

- Minimize the use of excessive force or pressure on the blade, as it can lead to blade deflection and early fatigue.

Implementing Preventive Maintenance Practices To Prolong Blade Life:

- Regularly clean the blades after each use to remove debris and prevent buildup, which can cause heat generation and affect cutting performance.

- Lubricate the blades to reduce friction and heat during operation.

- Inspect the blades for damage, such as cracks or missing teeth, and promptly address any issues.

- Store the saw blades properly to prevent rusting and ensure their longevity.

By following these proactive blade preservation techniques, you can significantly extend the life of your saw blades and maximize their cutting efficiency. Remember, regular maintenance and proper usage are key to achieving optimal performance and reducing the frequency of blade replacements.

Frequently Asked Questions On How Can I Extend The Life Of My Saw Blades?

How Can I Make My Saw Blades Last Longer?

To make your saw blades last longer, follow these tips: 1. Use the appropriate blade for each material and task. 2. Keep the blades clean and free from debris. 3. Ensure proper blade tension and alignment. 4. Avoid overheating by using lubrication and letting the blade cool down.

Will Wd40 Clean Saw Blades?

Yes, WD40 can clean saw blades effectively.

Should You Lubricate Saw Blade?

Yes, it’s important to lubricate the saw blade for smoother cutting and to prolong its lifespan.

How Long Should A Saw Blade Last?

A saw blade typically lasts around 8 to 10 hours of continuous use before needing to be replaced.

Conclusion

To ensure the longevity of your saw blades, implementing proper maintenance and storage practices is key. Regular cleaning, lubrication, and careful handling will help to prevent rust, keep the blades sharp, and minimize wear and tear. It’s also essential to choose the right blade for each task, ensuring that it is compatible with the material you are cutting.

Additionally, using a saw blade with a high tooth count can extend its life as it distributes wear across more teeth. Sharpening the blades when necessary and replacing them when they become dull or damaged will further prolong their lifespan and maintain optimal cutting performance.

Lastly, remember to store your saw blades in a clean, dry environment, away from moisture and corrosive substances. By following these tips, you’ll maximize the lifespan of your saw blades, saving you time and money in the long run.