To keep your tools in optimal condition for longer, regularly clean and lubricate them. Clean off dirt and debris after each use and apply an appropriate lubricant to prevent rust and keep moving parts functioning smoothly.

Maintaining your tools in this way will help extend their lifespan and ensure they remain in good working condition. Keeping your tools in optimal condition is crucial to getting the best performance out of them and making them last longer.

Whether you’re a DIY enthusiast or a professional tradesperson, taking care of your tools is an essential part of your workflow. Regular maintenance not only prevents wear and tear but also helps you avoid costly replacements. We will discuss some simple yet effective ways to keep your tools in optimal condition for longer. By implementing these practices, you can ensure that your tools remain reliable, durable, and ready to tackle any task at hand. So let’s dive in and explore how you can prolong the life of your tools and save both time and money in the long run.

Inspect And Clean Regularly

Inspecting and cleaning your tools regularly is crucial to ensure their optimal condition and longevity. Regular maintenance helps identify damage or wear, allowing for timely repairs and preventing further deterioration. Keep your tools clean to prevent rust and ensure smooth functionality for extended usage.

Importance Of Regular Inspection And Cleaning

Regularly inspecting and cleaning your tools is crucial for maintaining their optimal condition. Not only does this help extend the lifespan of your tools, but it also ensures their performance and functionality remain top-notch. By incorporating this practice into your routine, you can save time and money by avoiding costly repairs or replacements in the long run.

Here are a few reasons why regular inspection and cleaning are important:

- Preventing damage: Regular inspection allows you to identify any signs of wear, rust, or damage on your tools. By catching these issues early on, you can take the necessary steps to prevent further damage and ensure that your tools continue to work effectively.

- Ensuring safety: Tools that are not properly maintained can pose safety hazards. Regular cleaning and inspection help uncover any faults or malfunctions that could potentially cause accidents or injuries. By addressing these issues promptly, you create a safer working environment for yourself and others.

- Improving efficiency: Clean tools perform better. Removing dirt, grease, or debris from your tools allows them to function at their best. Regular inspection and cleaning can optimize their performance, resulting in more efficient and accurate work.

Recommended Cleaning Tools And Materials

To effectively clean your tools, it is important to have the right cleaning tools and materials on hand. Here are some recommended cleaning tools and materials you may need:

- Soft-bristle brush or toothbrush: Ideal for removing dirt, rust, or debris from the surface of your tools without scratching them.

- Microfiber cloth: Perfect for wiping down your tools and removing any residual dirt or grime.

- Degreaser solution: Helps to dissolve grease or oil buildup on your tools.

- Rust remover: Useful for eliminating rust from metal tools and preventing further corrosion.

- Lubricant: Ensures smooth movement of tools with moving parts, reducing friction and preventing wear.

Step-By-Step Guide For Cleaning Different Types Of Tools

Cleaning different types of tools requires specific approaches to ensure their longevity and optimal performance. Here is a step-by-step guide you can follow for cleaning various types of tools:

- Hand tools:

- Remove any loose dirt or debris from the surface using a soft-bristle brush.

- Wipe the tools down with a microfiber cloth to remove any remaining dirt.

- For stubborn dirt or rust, use a mild degreaser solution or rust remover.

- Dry the tools thoroughly with a clean cloth to prevent moisture-related damage.

- Apply a light coat of lubricant to moving parts for smooth operation.

- Power tools:

- Unplug the tool or remove the battery before cleaning.

- Use a brush or compressed air to remove dust and debris from vents and crevices.

- Wipe down the tool’s exterior with a microfiber cloth.

- Clean any attachments or accessories separately according to their specific cleaning requirements.

- Apply lubricant or grease to relevant parts as recommended by the manufacturer.

- Garden tools:

- Remove any soil or debris from the tools using a brush or hose.

- Scrub the tools with a mild soap and water solution to remove stubborn dirt or stains.

- For rusty areas, use a rust remover and scrub gently.

- Rinse the tools thoroughly and dry them completely to prevent rust.

- Apply a thin layer of oil or WD-40 to metal parts for protection against rust.

By incorporating these cleaning steps into your maintenance routine, you can ensure that your tools remain in optimal condition for longer, maximizing their lifespan and performance. Remember to always refer to the manufacturer’s guidelines for specific cleaning recommendations on your tools.

Proper Storage Techniques

Proper storage techniques are essential for keeping your tools in optimal condition for longer. By storing them in a clean and dry environment, organizing them systematically, using protective cases or storage solutions, and regularly inspecting and maintaining them, you can extend their lifespan and ensure their effectiveness when you need them.

The Impact Of Improper Storage On Tool Longevity

When it comes to preserving the lifespan of your tools, proper storage techniques play a crucial role. Failing to store your tools correctly can lead to various issues, including rust, dullness, and even damage to the tool itself. To ensure that your tools stay in optimal condition for longer, it’s essential to understand the impact of improper storage.

Here are a few key points to consider:

- Exposure to moisture: When tools are left in damp or humid environments, they become vulnerable to rust and corrosion. This can weaken the tool’s integrity and compromise its functionality.

- Lack of protection: Tools left scattered or piled up haphazardly are prone to dents, scratches, and other physical damage. Without proper protection, they are more likely to lose their effectiveness over time.

- Misplacement and loss: Without a designated storage system, tools often end up misplaced or lost altogether. This not only hinders your productivity, but it also means you may need to spend additional money replacing lost tools.

Choosing The Right Storage Solutions

Selecting the appropriate storage solutions for your tools is essential for maintaining their longevity. Here are some options that can help you keep your tools organized and well-protected:

- Toolbox or tool chest: These portable storage options are designed to hold a variety of tools securely. They typically feature compartments and drawers that allow for easy organization and accessibility.

- Wall-mounted storage: Installing hooks, pegboards, or wall-mounted racks provides a space-saving solution. This approach ensures that your tools are easily visible and within reach whenever you need them.

- Tool cabinets: Similar to a toolbox, a tool cabinet offers more significant storage capacity. They often feature adjustable shelves, allowing you to customize the interior layout to suit your specific tool collection.

Tips For Organizing And Protecting Your Tools

Proper organization and protection are essential for maximizing the lifespan of your tools. Here are some practical tips to help you achieve this:

- Clean and dry tools before storage: Before stowing away your tools, make sure to remove any dirt or debris. Wipe them clean and ensure they are completely dry to prevent moisture damage.

- Use tool-specific storage compartments: Invest in storage solutions that have compartments designed to fit specific tool types. This helps prevent them from tumbling around and causing unnecessary wear.

- Implement a labeling system: Labeling your storage compartments can make it easier to locate and retrieve specific tools. Consider using color-coded labels or tags for added convenience.

- Use protective coatings: Applying a thin layer of protective coating, such as lubricant or wax, can help prevent rust and corrosion on metal tools.

- Store in appropriate conditions: Keep your tools in a dry, well-ventilated area away from extreme temperatures. Consider using moisture-absorbing products, like silica gel packs, to maintain an optimal environment.

By implementing proper storage techniques, you can significantly extend the lifespan of your tools. Taking the time to organize and protect them appropriately will not only save you time and money but also ensure that your tools remain in optimal condition for longer.

So, give your tools the love and care they deserve by storing them properly.

Maintenance And Lubrication

Proper maintenance and lubrication are essential for keeping your tools in optimal condition for longer. Regular cleaning and oiling, along with storing them in the right environment, can prevent rust and wear, ensuring their longevity and efficiency in the long run.

Understanding The Importance Of

Regular maintenance and proper lubrication are crucial factors in keeping your tools in optimal condition for longer. Neglecting these essential tasks can lead to decreased performance, premature wear and tear, and even costly repairs or replacements. By prioritizing maintenance and lubrication, you can extend the lifespan of your tools and ensure they function at their best when you need them most.

Below, we’ll delve into the significance of these practices and provide you with a step-by-step guide to help you maintain and lubricate your tools effectively.

Recommended Lubricants For Different Types Of Tools

Using the right lubricants for your tools is vital for their proper functioning and longevity. Different tools require specific lubricants to ensure optimal performance. Here are some recommended lubricants for different types of tools:

- Silicone spray lubricant: Ideal for power tools, electrical equipment, and mechanisms that require a dry lubricant to prevent dust or debris accumulation.

- White lithium grease: Suitable for hinges, locks, chains, and metal-to-metal contacts as it provides excellent lubrication and corrosion resistance.

- Multi-purpose oil: Versatile lubricant that works well on various tools such as hand tools, garden equipment, and small machinery.

Remember to consult your tool’s manufacturer or the user manual for specific lubrication recommendations.

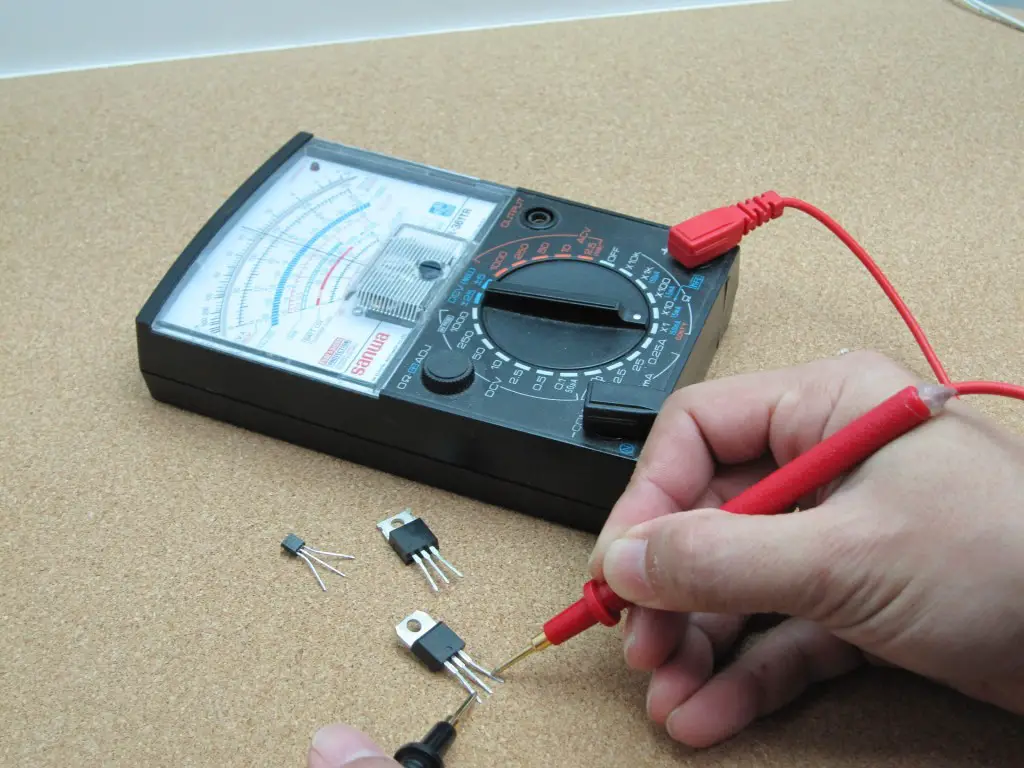

Step-By-Step Guide For Proper Maintenance And Lubrication

Maintaining and lubricating your tools doesn’t have to be a complicated process. Follow this step-by-step guide to ensure you’re on the right track:

- Clean your tools:

- Remove any dirt, debris, or dust from the tool’s surface using a brush or a soft cloth.

- For stubborn grime, use a mild detergent or specialized cleaning solution, avoiding any abrasive substances that could damage the tool’s finish.

- Dry the tools thoroughly to prevent moisture buildup, which can cause rust.

- Inspect for damages:

- Check for any signs of wear and tear, such as loose parts, cracks, or frayed cables.

- If you spot any damages, address them immediately to prevent further deterioration.

- Lubricate moving parts:

- Apply the appropriate lubricant to the tool’s moving parts, ensuring even distribution.

- Use just enough lubricant to prevent excessive accumulation or dripping.

- Test and operate the tool:

- After lubricating, test the tool to ensure smooth and efficient operation.

- Pay attention to any unusual noises or vibrations, as they may indicate underlying issues.

- Store properly:

- Clean and organize your tools after each use to prevent corrosion or damage caused by improper storage.

- Consider using toolboxes, cabinets, or designated storage systems to protect your tools from dust, moisture, and accidental impact.

Regularly following these maintenance and lubrication practices will significantly enhance the performance and longevity of your tools. Remember, each tool may have specific requirements, so refer to the manufacturer’s instructions for optimal care and maintenance. By dedicating a little time and effort, you can keep your tools in excellent condition, saving both time and money in the long run.

Avoiding Common Mistakes

Learn how to avoid common mistakes and keep your tools in optimal condition for longer. Discover helpful tips and techniques that will help you maintain your tools in the best possible way, ensuring their longevity and performance.

Common Mistakes That Can Damage Tools:

- Storing tools improperly: Leaving tools exposed to moisture, extreme temperatures, or direct sunlight can lead to rusting, warping, or other forms of damage.

- Neglecting cleaning and maintenance: Failing to clean tools after use allows dirt, debris, and corrosive materials to accumulate, eventually causing deterioration.

- Overexertion: Using tools beyond their recommended limits can cause excessive wear and tear, leading to premature breakdown.

- Poor handling techniques: Mishandling tools, such as using the wrong grip or applying excessive force, can result in damage to the tool or injury to the user.

- Ignoring manufacturer instructions: Neglecting to follow the recommended guidelines for tool usage, maintenance, and storage can significantly reduce their lifespan.

Tips For Avoiding These Mistakes:

- Invest in proper storage solutions: Utilize toolboxes, tool cabinets, or wall-mounted racks to neatly store tools in a dry and controlled environment.

- Clean tools after every use: Wipe away any dirt, debris, or moisture using a clean cloth or brush. For stubborn residues, use a specialized cleaning solution suitable for the tool’s material.

- Regularly inspect tools: Routinely check for any signs of wear, damage, or loose parts. This allows for early identification of problems and facilitates timely repairs or replacements.

- Follow the recommended usage guidelines: Adhere to the manufacturer’s instructions regarding load limits, speed settings, and appropriate accessories to ensure the tools are not overstressed.

- Practice proper handling techniques: Use tools with the correct grip, and apply force in a controlled manner. Avoid using excessive force or using tools for tasks they are not designed for.

- Store tools in designated compartments: Keep tools organized in their respective storage compartments, preventing them from hitting or scratching each other.

- Protect tools from extreme conditions: Shield tools from exposure to moisture, direct sunlight, and extreme temperatures by storing them in climate-controlled areas or using protective cases or covers.

- Schedule regular maintenance: Carry out routine maintenance tasks such as oiling, sharpening, or blade replacements as recommended by the manufacturer.

Remember, by avoiding common mistakes, implementing proper tool handling techniques, and providing regular maintenance, you can extend the lifespan and functionality of your tools, saving both time and money in the long run.

Sharpening And Calibration

Proper sharpening and calibration techniques are essential for preserving the longevity of your tools. By regularly maintaining and fine-tuning them, you can keep your tools in optimal condition, ensuring their effectiveness and durability for an extended period.

Importance Of Keeping Tools Sharp And Calibrated

Maintaining sharpness and proper calibration for your tools is crucial for their optimal performance and longevity. Regularly sharpening and calibrating your tools not only ensures efficient usage but also enhances their safety. Dull or misaligned tools can lead to subpar results, increased effort, and even accidents.

By prioritizing tool maintenance, you can maximize productivity and save money on frequent replacements.

Methods And Tools For Sharpening Different Types Of Tools

Different tools may require varying methods or specialized tools for sharpening. Here are some common methods and corresponding tools for sharpening different types of tools:

- Hand Tools:

- Whetstone: Ideal for sharpening blades, chisels, and knives.

- Honing Guide: Helps maintain consistent and precise angles while sharpening plane irons and chisels.

- Power Tools:

- Bench Grinder: Effective for sharpening larger, heavier tools like lawnmower blades and axes.

- Grinding Wheels: Best suited for high-speed sharpening of drill bits, turning tools, and other small tools.

- Garden Tools:

- Mill Files: Suitable for sharpening pruners, loppers, and garden shears.

- Rotary Tool with Grinding Attachment: Efficient for sharpening the blades of hedge trimmers, shovels, and hoes.

Step-By-Step Guide For Sharpening And Calibrating Tools

Follow these steps to sharpen and calibrate your tools effectively:

- Select the appropriate sharpening method and tool mentioned above.

- Ensure you have a safe and well-lit workspace.

- Securely fasten the tool you wish to sharpen or calibrate.

- Check the tool’s condition for any noticeable damage or excessive wear.

- If needed, clean the tool to remove dirt, rust, or debris.

- Begin sharpening by holding the tool at the correct angle determined by its design, using a consistent motion.

- Sharpen the tool evenly on both sides to maintain balance.

- Periodically check for sharpness by testing the tool’s cutting ability.

- Once sharp, remove any burrs or rough edges using a honing guide or fine-grit sandpaper.

- For calibration, double-check the alignment or adjustments of tools that require precise measurements, such as levels or gauges.

- Confirm that the tool is properly calibrated and ready for use.

Regularly repeating this process will ensure your tools remain in optimal condition, increasing their overall lifespan and effectiveness.

Remember, sharpening and calibrating your tools is a necessary investment of time and effort, promising countless benefits in return. With well-maintained tools, you can tackle projects with confidence and achieve exceptional results.

Protecting Against Rust And Corrosion

To keep your tools in optimal condition for longer, it is important to protect them against rust and corrosion. Ensure proper storage in dry environments, use rust-inhibiting products, and clean and dry your tools after use to prevent damage and prolong their lifespan.

How Rust And Corrosion Can Affect Tools

Rust and corrosion can significantly compromise the performance and lifespan of your tools. When left unaddressed, these issues can render your tools useless and lead to expensive replacements. Understanding how rust and corrosion can affect your tools is crucial in maintaining their optimal condition.

- Rust: Rust occurs when iron or steel tools are exposed to moisture or oxygen. It forms a reddish-brown coating on the surface of the metal, causing it to weaken and deteriorate over time. Rust can hinder the proper functioning of moving parts, result in poor cutting or gripping abilities, and lead to overall inefficient tool performance.

- Corrosion: Corrosion is the general term used to describe the process of metal deterioration caused by chemical reactions. It can occur in various forms, such as pitting, cracking, or discoloration. Corrosion not only affects the appearance of the tools but can also cause structural damage, rendering them unreliable and unsafe to use.

Tips For Preventing Rust And Corrosion

Preventing rust and corrosion is essential in prolonging the life and usability of your tools. By following these simple tips, you can minimize the risk and keep your tools in optimal condition:

- Keep tools dry: Moisture is a primary factor that contributes to rust and corrosion. After each use, ensure that your tools are thoroughly dried before storing them. Wipe off any moisture with a clean, dry cloth and consider using compressed air to remove water from hard-to-reach areas.

- Apply protective coating: To provide an extra layer of defense against rust, consider applying a rust-inhibiting coating on your tools. Products such as rust-preventive sprays or waxes can help seal the surface and prevent moisture from coming into contact with the metal.

- Store tools properly: Proper storage plays a vital role in preventing rust and corrosion. Store your tools in a cool, dry place to minimize exposure to moisture and humidity. Consider using silica gel packets or a dehumidifier in the storage area to absorb excess moisture.

- Clean tools regularly: Regular cleaning is essential to remove dirt, debris, and other contaminants that can contribute to rust and corrosion. Use a mild detergent or cleaner suitable for the specific tool material, rinse thoroughly, and dry completely before storing.

Recommended Rust Prevention Products And Techniques

In addition to the preventive measures mentioned above, utilizing specific rust prevention products and techniques can further safeguard your tools from rust and corrosion:

- Rust inhibitors: There are various rust inhibitor products available in the market, including sprays, oils, and coatings. These products contain corrosion-resistant compounds that create a protective barrier on the metal surface, inhibiting rust formation.

- Desiccants: Desiccants, such as silica gel packets or moisture-absorbing bags, are useful in moisture-prone storage areas. Placing these desiccants alongside your tools helps absorb excess moisture, reducing the likelihood of rust and corrosion.

- VCI technology: Vapor corrosion inhibitors (VCI) emit molecules that attach to metal surfaces, forming a protective layer. VCI products, such as rust-preventive films or papers, can be used to wrap the tools before storage, effectively inhibiting rust and corrosion.

By implementing these preventive measures and utilizing rust prevention products and techniques, you can effectively protect your tools against rust and corrosion, ensuring their optimal condition for longer durations.

Safe Handling And Usage Practices

To keep your tools in optimal condition for longer, it is important to practice safe handling and usage practices. By using them correctly, storing them properly, and performing regular maintenance, you can extend the lifespan of your tools and ensure they continue to perform at their best.

Proper Techniques For Using And Handling Tools

- Always read and understand the user manual or instructions provided by the manufacturer.

- Ensure that you have the necessary skills and knowledge to safely operate the tool.

- Use the tool only for its intended purpose and within its designated limits.

- Maintain a firm grip on the tool at all times and use both hands when required for stability.

- Avoid applying excessive force or pressure that could lead to tool damage or injury.

- Keep cutting edges and blades sharp to prevent slippage and improve effectiveness.

- Clean the tool thoroughly after each use to remove debris and prevent build-up.

- Store tools in a dry and secure place to avoid rusting or accidental damage.

- When transporting tools, secure them properly to prevent them from shifting or falling.

- Regularly inspect tools for any signs of wear, damage, or malfunction and replace or repair them promptly.

Importance Of Wearing Appropriate Safety Gear

- Always wear safety goggles, gloves, and any other protective gear recommended for the specific tool and task.

- Safety goggles protect your eyes from flying debris, sparks, and other potential hazards.

- Gloves provide grip, protect your hands from cuts, abrasions, and burns, and reduce vibration impacts.

- Use ear protection, such as earplugs or earmuffs, when operating loud tools to prevent hearing damage.

- Wearing appropriate safety gear significantly reduces the risk of injuries and enhances your overall safety.

Tips For Avoiding Accidents And Prolonging Tool Lifespan

- Keep your work area clean and well-lit to minimize tripping hazards and improve visibility.

- Maintain a clear mind and avoid distractions when using tools to stay focused on the task at hand.

- Unplug power tools when not in use or when performing maintenance, repairs, or adjustments.

- Avoid using tools in wet or damp conditions to reduce the risk of electrical shock.

- Follow proper electrical safety guidelines, such as using a grounded outlet and inspecting cords for damage.

- Never carry a tool by its cord or hose, as it can lead to cord damage or accidental disconnect.

- Use clamps or a vise to secure workpieces for stability and to keep your hands free from potential hazards.

- Never force a tool to perform beyond its capabilities as this can damage the tool and increase the risk of accidents.

- Regularly lubricate moving parts and conduct routine maintenance recommended by the manufacturer.

- Store tools in their original cases or use designated storage solutions to protect them from dust and damage.

Remember, practicing safe handling and usage techniques not only prevents accidents and injuries but also ensures that your tools are kept in optimal condition for longer. By following these guidelines, you can prolong the lifespan of your tools, save money on replacements, and maintain a safe work environment.

Professional Tool Maintenance Services

Optimize the lifespan of your tools with professional maintenance services. Keep your tools in peak condition for longer with expert care and ensure optimal performance.

Overview Of Professional Tool Maintenance Services:

- Professional tool maintenance services are specialized services provided by experienced technicians who have expertise in handling and repairing various tools and equipment.

- These services aim to keep your tools in optimal condition, ensuring they perform at their best and have an extended lifespan.

- With professional tool maintenance, you can expect thorough inspections, cleaning, lubrication, adjustments, and repairs as needed for your tools.

When To Consider Professional Maintenance:

- While regular maintenance can be performed by the tool owner, certain situations call for the expertise of professionals. Consider professional maintenance services in the following scenarios:

- When your tools require intricate repairs or complex adjustments that you are not confident in handling.

- If you lack the time, knowledge, or tools required to perform comprehensive maintenance on your own.

- When your tools are experiencing persistent issues or are not performing up to par despite your efforts.

Benefits Of Professional Maintenance And Repair Services:

- Expertise and experience: Professional technicians possess in-depth knowledge of different tools and their functionality, allowing them to diagnose and address problems accurately.

- Save time and effort: By entrusting your tools to professionals, you can focus on other tasks while they handle the maintenance and repair work.

- Cost-effective: Regular maintenance by professionals can help prevent major breakdowns, saving you from costly repairs or having to replace tools prematurely.

- Increased tool lifespan: Proper maintenance and prompt repairs can significantly extend the lifespan of your tools, ensuring you get the most out of your investment.

- Optimal performance: Professional maintenance services tune your tools to perform at their highest capacity, enhancing their efficiency and productivity.

- Reduced downtime: Well-maintained tools are less likely to experience unexpected breakdowns, minimizing downtime and disruption to your work.

Remember, professional tool maintenance services are designed to keep your tools in top-notch condition. By considering such services, you can benefit from the expertise of professionals, ensure optimal tool performance, and prolong the lifespan of your valuable tools.

Credit: www.amazon.com

Frequently Asked Questions For How Can I Keep My Tools In Optimal Condition For Longer?

How Do You Keep Tools In Good Condition At All Times?

Regular maintenance, including cleaning and lubricating, ensures tools remain in good condition at all times.

How Do You Prolong Tools?

To prolong tools, follow these steps: 1. Keep tools clean and dry after use. 2. Store them in a clean, moisture-free area. 3. Lubricate moving parts regularly. 4. Use tools for their intended purposes and avoid excessive force.

How Often Should I Clean My Tools?

Tools should be cleaned after every use to prevent rust and debris buildup. Regular cleaning will help maintain their performance and longevity.

What Is The Best Way To Store Tools?

Store tools in a dry, well-ventilated area to prevent moisture damage. Use toolboxes, racks, or pegboards to organize and protect them from rust or accidental damage.

Conclusion

Taking care of your tools is essential for maintaining their optimal condition and prolonging their lifespan. By regularly cleaning and inspecting your tools, you can prevent rust, corrosion, and other damage that could affect their performance. Storing them properly in a clean and dry environment also helps to keep them in top shape.

Additionally, lubricating moving parts and sharpening cutting edges will ensure that they remain efficient and effective. Investing in high-quality tools and using them correctly will further enhance their longevity. Remember to follow manufacturer’s instructions and avoid any harsh chemicals or improper usage.

By following these simple tips, you can continue to rely on your tools for years to come, saving both time and money in the long run. Don’t underestimate the power of regular maintenance – it’s the key to keeping your tools in optimal condition for longer.