To maintain precision tools for accurate results, clean them regularly and store them in a controlled environment. Precision tools require regular maintenance to ensure accurate results.

Keeping the tools clean and free from debris is essential for their optimal performance. Additionally, storing them in a controlled environment that is free from extreme temperatures or humidity can help preserve their accuracy. Properly lubricating movable parts and inspecting for any signs of wear or damage is also important.

By following these practices, you can prolong the lifespan of your precision tools and ensure they consistently deliver accurate results.

Credit: www.amazon.com

Understanding The Importance Of Tool Maintenance

Understanding the importance of tool maintenance is crucial for achieving accurate results when using precision tools. By properly maintaining and caring for your tools, you can ensure their longevity and reliability, ultimately leading to better performance and precision in your work.

Maintaining precision tools is crucial for achieving accurate and consistent results in various industries. Regular maintenance not only extends the lifespan of these tools but also enhances their performance, ensuring that they operate at their full potential. By prioritizing tool maintenance, professionals can uphold the highest levels of accuracy in their work.

Let’s delve into the reasons why regular maintenance is crucial for precision tools.

Why Regular Maintenance Is Crucial For Precision Tools:

- Extend tool lifespan: Regular maintenance helps prevent premature wear and tear of precision tools, ultimately extending their lifespan. By caring for these tools properly, professionals can avoid costly replacements and maximize their investment.

- Improve tool performance: Through regular maintenance, professionals can optimize the performance of their precision tools. Cleaning, lubricating, and calibrating these tools regularly ensures that they function smoothly, minimizing the risk of errors and malfunctions.

- Ensure accuracy in results: Maintaining precision tools plays a fundamental role in ensuring accurate and precise results. Over time, tools can develop slight imperfections or lose their calibration, leading to inaccuracies in measurements or cuts. Regular maintenance activities, such as calibration checks and adjustments, help maintain the desired level of precision.

Maintaining precision tools is essential for anyone who relies on accurate and consistent results. Regular maintenance not only prolongs the lifespan of these tools but also enhances their performance, allowing professionals to achieve precise measurements and cuts. By prioritizing maintenance activities, individuals can avoid costly repairs, improve overall efficiency, and uphold the highest standards of accuracy in their work.

Essential Maintenance Practices

Accurate results are achieved by adhering to essential maintenance practices for precision tools. To ensure accuracy, regular cleaning, proper storage, lubrication, and calibration are necessary. Additionally, periodic inspections and quality control measures must be implemented to maintain the optimal functioning of the tools.

Trustworthy maintenance practices enhance accuracy and extend the lifespan of precision tools.

Precision tools are essential for achieving accurate results in various industries, including manufacturing, engineering, and woodworking. To ensure the longevity and accuracy of these tools, it is crucial to implement proper maintenance practices. By following these essential maintenance practices, you can extend the lifespan of your precision tools and maintain their accuracy over time:

Cleaning And Storing Precision Tools Properly:

- Regularly cleaning your precision tools helps to remove dirt, debris, and other contaminants that can impact their performance.

- After use, wipe down the tools with a clean, dry cloth to remove any residue.

- Store them in a clean and dry environment to prevent corrosion or rusting.

Choosing The Right Cleaning Materials:

- Utilize non-abrasive cleaning materials such as soft brushes, lint-free cloths, or compressed air to avoid damaging the tools.

- Avoid using harsh chemicals that could corrode or harm the tools’ surfaces.

Cleaning Techniques For Different Tool Types:

- Each precision tool requires specific cleaning techniques.

- For delicate instruments like microscopes or calipers, use gentle cleaning methods, such as softly brushing away contaminants or using compressed air.

- For cutting tools, such as drills or saw blades, remove any residues with a suitable cleaning solvent or degreaser.

Importance Of Proper Storage Conditions:

- Store precision tools in a designated toolbox or case to protect them from dust, moisture, and potential damage.

- Use protective covers or sheaths for fragile components to shield them from scratches or impacts.

Regular Inspection And Calibration:

- Perform regular inspections to identify any signs of wear, damage, or misalignment.

- This includes checking for loose or damaged parts, worn-out blades, or inaccurate measurements.

- Regular calibration ensures that your precision tools maintain their accuracy.

Identifying Signs Of Wear And Damage:

- Look out for visible signs of wear, such as chipped edges, bent blades, or dents.

- Pay attention to any unusual noises, vibrations, or inconsistencies in measurements, as they can indicate underlying problems.

Importance Of Calibration For Accuracy:

- Calibration is vital to ensure the accuracy and reliability of precision tools.

- Over time, these tools may lose their precision due to environmental factors, regular use, or aging. Calibration restores their accuracy and consistency.

Calibration Methods For Different Tools:

- Different tools require specific calibration methods.

- For measuring instruments like dial indicators or micrometers, use calibration standards or certified calibration technicians.

- Power tools, such as torque wrenches or drills, may require torque calibration or motor speed adjustment.

Lubrication And Proper Tool Handling:

- Lubrication plays a crucial role in the proper functioning of precision tools.

- Applying suitable lubricants prevents friction, reduces wear, and extends the tools’ lifespan.

- Handle the tools with care, avoiding excessive force, dropping, or mishandling that could result in damage.

Benefits Of Lubrication:

- Lubrication minimizes wear and tear on moving parts.

- It reduces the chances of rust or corrosion, improving the tools’ overall performance and longevity.

Types Of Lubricants For Different Tools:

- Different precision tools require specific lubricants suited to their materials and mechanisms.

- For example, silicone-based lubricants are excellent for plastics and elastomers, while oil-based lubricants work well for metals.

Best Practices For Tool Handling To Prevent Damage:

- To avoid damage to precision tools, follow these best practices:

- Store them in their designated cases or toolboxes after use.

- Handle them with clean hands to prevent fingerprints and potential contamination.

- Avoid placing heavy objects on top of delicate tools, as it may lead to deformation or breakage.

By implementing these essential maintenance practices, you can ensure that your precision tools remain in optimal condition and continue to provide accurate results. Regular cleaning, proper storage, calibration, lubrication, and cautious handling are key to maintaining the longevity and performance of these valuable instruments.

Tips For Specific Precision Tools

Discover essential tips to maintain precision tools and achieve accurate results. Learn how proper care, regular cleaning, and storage can extend the lifespan and functionality of your precision tools. Enhance their performance and ensure precise measurements with these insightful techniques.

Maintaining Precision Measuring Tools

- Clean delicate measuring surfaces regularly to prevent dirt and debris from affecting accuracy.

- Use a soft, lint-free cloth or brush to gently remove any particles.

- Avoid using harsh chemicals or abrasive materials that could scratch or damage the measuring surfaces.

- Store measuring tools in a clean and dry environment to protect them from moisture and contamination.

- Check for any signs of wear or damage and address them promptly to ensure accurate results.

- Follow the manufacturer’s instructions for proper handling and calibration of the measuring tools.

Calibrating Measuring Instruments Accurately

- Regularly check and calibrate measuring instruments to maintain accuracy.

- Use calibrated reference standards or tools to verify measurement results.

- Follow the manufacturer’s guidelines for calibration intervals and procedures.

- Make adjustments as necessary to bring the instrument back to its accurate state.

- Keep a record of calibration dates and results for reference and quality control purposes.

Protecting Against Temperature And Humidity Variations

- Store precision tools in a controlled environment to minimize the effects of temperature and humidity fluctuations.

- Extreme temperatures and high humidity can cause expansion or contraction, affecting the precision of the tools.

- Use proper protective cases or storage boxes to shield the tools from outside elements.

- Allow tools to acclimate to the surrounding environment before use to avoid temperature-related inaccuracies.

- Use temperature and humidity monitoring devices to ensure the ideal conditions for storing precision tools.

Caring For Precision Cutting Tools

- Clean cutting tools after each use to remove any debris or residue that may affect their performance.

- Use a non-abrasive cleaning solution and a soft cloth to wipe down the tools.

- Inspect the cutting edges for any signs of damage or dullness.

- Sharpen or hone cutting tools regularly to maintain their sharpness and precision.

- Follow the manufacturer’s recommendations for proper sharpening angles and techniques.

Sharpening And Honing Techniques

- Use appropriate sharpening tools, such as sharpening stones or honing guides, based on the type of cutting tool.

- Follow the correct sharpening angles and techniques for optimal results.

- Use consistent pressure and motion while sharpening to maintain even edges.

- Regularly check the sharpness of the cutting tool during the sharpening process.

- After sharpening, remove any burrs or rough edges with a honing stone or fine-grit sandpaper.

Proper Storage To Avoid Blade Damage

- Store cutting tools in a dry and secure location to protect the blades from moisture, rust, and accidental damage.

- Use blade guards or sheaths to cover the cutting edges and prevent accidental cuts or damage.

- Avoid storing cutting tools in cluttered or crowded spaces where they could be easily bumped or knocked over.

- Keep cutting tools separate from other tools or materials to avoid unnecessary contact and potential damage.

- Regularly inspect stored tools for any signs of wear, damage, or deterioration.

Maintaining Cutting Edges For Optimal Performance

- Regularly check the cutting edges for sharpness and signs of wear during use.

- Touch up the edges as needed with a sharpening tool to maintain optimal cutting performance.

- Avoid using excessive force or cutting materials beyond the tool’s capabilities, as it can cause premature wear.

- Clean the cutting edge after each use to prevent build-up of materials that could affect performance.

- Handle cutting tools with care to avoid accidental damage or chipping of the cutting edges.

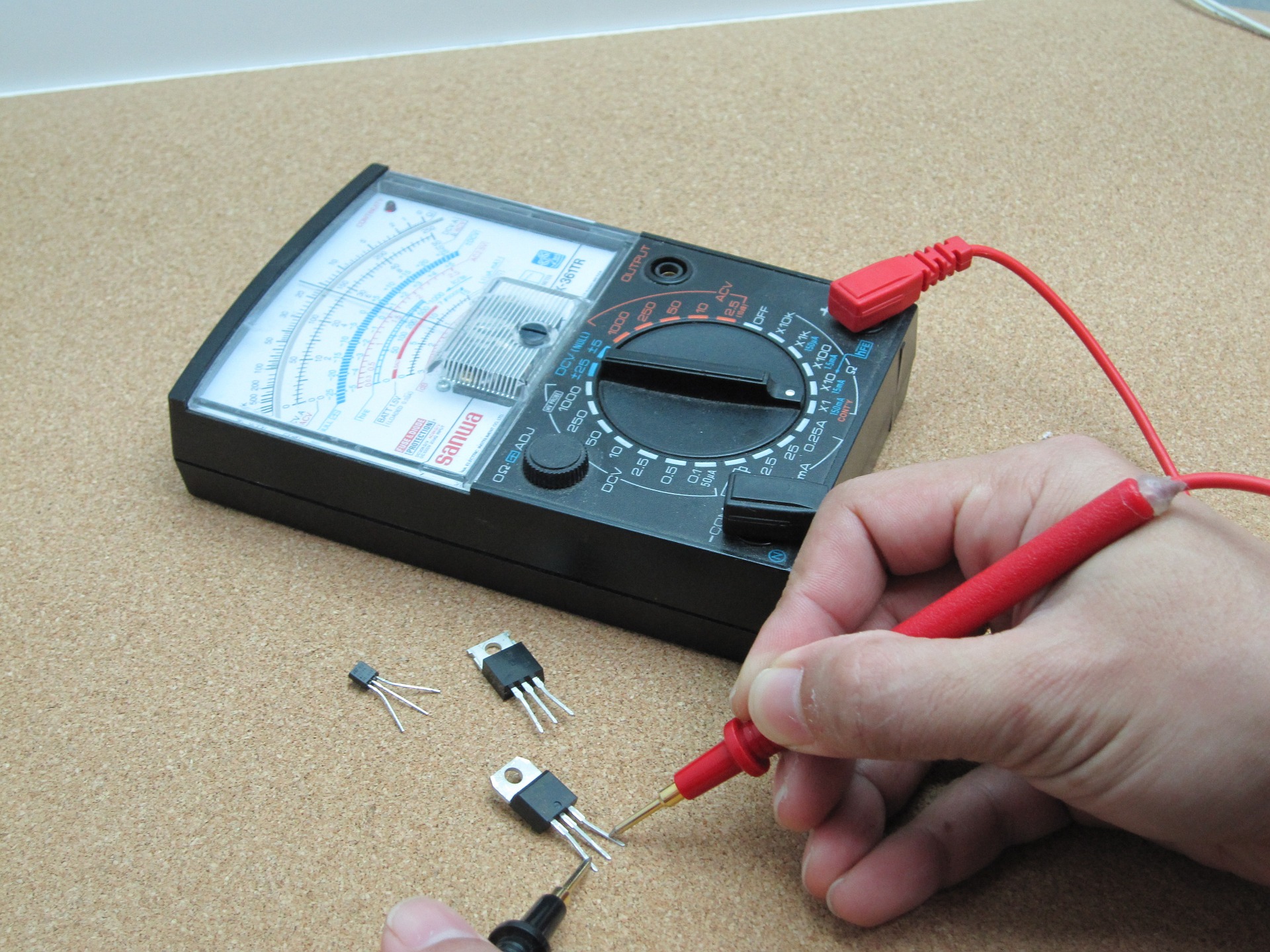

Maintaining Electronic Precision Tools

- Protect electronic precision tools from dust and moisture by using appropriate cases or covers.

- Regularly clean the tools using compressed air or a soft brush to remove any loose particles.

- Avoid exposing electronic tools to extreme temperatures or humidity.

- Check and replace batteries as needed to ensure proper functioning.

- Follow the manufacturer’s instructions for battery maintenance and replacement.

Safeguarding Against Dust And Moisture

- Store electronic precision tools in a clean and dry environment to prevent dust and moisture from causing damage.

- Use protective cases or covers to shield the tools from outside elements.

- Regularly clean the tools using appropriate methods, such as compressed air or a soft brush, to remove dust and debris.

- Keep any connectors or ports covered when not in use to avoid moisture accumulation.

- Take extra precautions when working in dusty or humid environments to protect electronic precision tools.

Battery Maintenance And Replacement

- Monitor battery life and performance regularly to ensure accurate and consistent results.

- Follow the manufacturer’s guidelines for battery maintenance, including charging, storage, and replacement.

- Store batteries in a cool and dry place to prolong their lifespan.

- Keep spare batteries on hand to avoid interruptions during use.

- Dispose of old batteries properly and according to local regulations.

Common Troubleshooting Techniques

- If experiencing issues with precision tools, consult the manufacturer’s troubleshooting guide or user manual.

- Check for loose connections or damaged components that may be affecting performance.

- Clean and inspect the tool for any signs of wear, damage, or malfunction.

- Perform any recommended calibration or adjustment procedures outlined in the user manual.

- Seek professional assistance if unable to resolve the issue or if the tool requires repairs.

Maintaining precision tools is crucial for obtaining accurate results in various industries. By implementing proper cleaning, calibration, storage, and maintenance techniques, you can ensure the longevity and effectiveness of these valuable tools.

Ensuring Safety During Tool Maintenance

Maintain precision tools for accurate results by prioritizing safety during tool maintenance. Follow proper handling techniques, ensure regular cleaning and lubrication, and conduct routine inspections to prevent accidents and maintain the longevity of your tools.

When it comes to maintaining precision tools for accurate results, it is crucial to prioritize safety precautions. Handling these tools requires careful attention, and taking certain steps can help protect you from potential hazards. Here are some key aspects to consider:

Importance Of Safety Precautions

- Wearing appropriate personal protective equipment: Always wear the necessary gear, such as safety glasses, gloves, and steel-toed shoes, to shield yourself from any potential accidents or injuries.

- Handling sharp or fragile tools safely: Use caution when working with sharp or fragile tools to prevent cuts, punctures, or breakages. Keep them properly stored and use protective covers where needed.

- Using caution with electrical and electronic components: When dealing with precision tools that involve electricity or electronic components, make sure to disconnect power sources and follow proper procedures to avoid electric shocks or damage to the tools.

- Proper disposal of hazardous waste: Dispose of waste materials generated during tool maintenance in accordance with local regulations. This may include oil, grease, cleaning solvents, or other hazardous substances.

- Identifying hazardous components in precision tools: Be mindful of hazardous components in your precision tools, such as lead in solder, and handle them with care. Follow safety guidelines provided by manufacturers to mitigate any risks associated with these components.

- Eco-friendly disposal options: Whenever possible, opt for eco-friendly disposal methods for significant components or parts that require disposal. Research recycling programs or facilities that accept precision tools and contribute to reducing environmental impact.

By adhering to these safety precautions during tool maintenance, you can minimize the risk of accidents, injuries, and environmental harm. Remember, your safety is paramount, while also ensuring the long-term precision and accuracy of your tools.

Frequently Asked Questions For How Can I Maintain Precision Tools For Accurate Results?

How Do You Maintain Precision Measuring Tools?

To maintain precision measuring tools: 1. Clean them regularly using a soft cloth and mild detergent, avoiding moisture. 2. Store them in a dry and low-dust environment to prevent damage. 3. Calibrate them periodically to ensure accurate readings. 4. Handle them carefully, avoiding dropping or mishandling that could affect their accuracy.

How Do You Maintain Accuracy And Precision When Measuring?

To maintain accuracy and precision when measuring, follow these guidelines: 1. Be careful and precise in your measurements by using accurate instruments. 2. Avoid mistakes and ensure accuracy by double-checking your measurements. 3. Calibrate measuring tools regularly to maintain accuracy over time.

4. Record measurements promptly and accurately to avoid any discrepancies.

How Do You Ensure Accurate Measurements?

To ensure accurate measurements, follow these guidelines: 1. Use precise instruments and tools. 2. Double-check measurements for accuracy. 3. Calibrate equipment regularly. 4. Follow proper measurement techniques.

What Is The Precision Tool Use For Getting Most Accurate Measurement?

The most accurate tool for measurement precision is a precision instrument. Its accurate readings ensure precision.

Conclusion

Maintaining precision tools is essential for achieving accurate and consistent results. By implementing a regular cleaning and lubrication routine, storing tools properly, and conducting periodic calibrations, you can ensure the longevity and performance of your equipment. It is also important to handle tools with care, avoiding dropping or mishandling them, as this can lead to damage or misalignment.

Additionally, investing in high-quality precision tools and replacing worn-out or damaged parts can contribute to maintaining accuracy. Remember to always follow the manufacturer’s guidelines and seek professional assistance when needed. By maintaining precision tools properly, you not only optimize their lifespan but also maximize your productivity and the quality of your work.

So, take the time and effort to care for your precision tools, and they will reward you with accurate and reliable results for years to come.