The essential tools needed for CNC woodworking projects include a CNC router, computer software, router bits, clamps, and safety equipment. CNC woodworking projects require specific tools to ensure precision and efficiency in cutting and shaping wood.

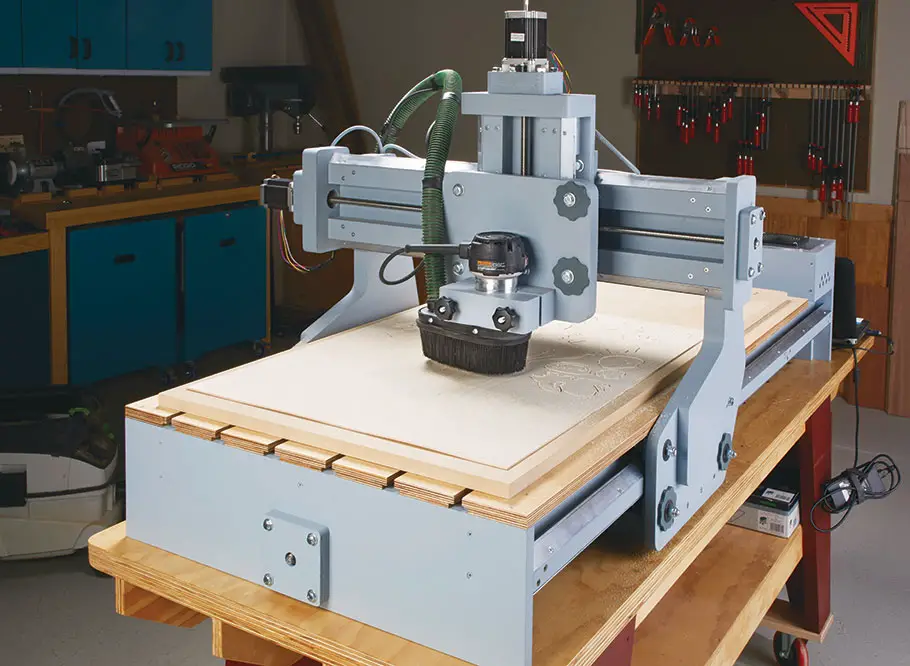

The primary tool is a CNC router machine that uses computer software to control the movement of the router and create intricate designs. Additionally, router bits are necessary for cutting and carving the wood. Clamps are essential for securely holding the workpiece in place during the routing process, while safety equipment such as gloves, goggles, and dust masks protect the operator from potential hazards.

These tools enable woodworkers to create intricate designs and achieve precise results in their CNC woodworking projects.

The Basics Of Cnc Woodworking

CNC woodworking projects require essential tools such as a CNC router, woodcutting bits, clamps, and measuring tools. These tools are crucial for precise and efficient woodworking tasks.

Understanding Cnc Woodworking

CNC woodworking, or Computer Numerical Control woodworking, is a modern approach that utilizes computer software and machinery to automate woodworking processes. This technology has revolutionized the woodworking industry, allowing for precise and efficient production of wooden components. By programming a design into a computer, the CNC machine can precisely cut, carve, and shape wood to create intricate and complex designs.

It offers numerous advantages over traditional woodworking methods, making it a popular choice among woodworkers of all skill levels.

Advantages Of Cnc Woodworking

Using CNC technology in woodworking projects provides a range of benefits that enhance productivity and precision. Here are some key advantages of CNC woodworking:

- Accuracy: CNC machines ensure precise and consistent results, eliminating the risk of human error and achieving high-quality craftsmanship.

- Efficiency: By automating the woodworking process, CNC machines can complete tasks faster than traditional methods, saving both time and labor.

- Reproducibility: CNC woodworking allows for the easy replication of designs, ensuring consistency in multiple products or components.

- Complex Designs: With CNC machines, intricate and detailed designs can be effortlessly achieved, bringing creativity and versatility to woodworking projects.

- Material Optimization: CNC machines can be programmed to maximize material usage, minimizing waste and optimizing cost-effectiveness.

- Safety: By reducing the need for manual operation, CNC woodworking reduces the risk of accidents and injuries associated with traditional woodworking tools.

The Role Of Technology In Cnc Woodworking

Technology plays a vital role in CNC woodworking, enabling woodworkers to leverage its advantages and achieve outstanding results. Here’s how technology intersects with CNC woodworking:

- Design Software: Specialized software programs, such as Computer-Aided Design (CAD) or Computer-Aided Manufacturing (CAM), facilitate the creation of digital designs that can be translated into CNC machine instructions.

- CNC Machines: These advanced machines consist of various components, including a control panel, spindle, and cutting tools. They interpret the digital design instructions and execute precise cuts and carvings on the wood.

- CNC Programming: Programming languages, such as G-code, are used to command CNC machines. Woodworkers can create these programs themselves or use existing ones to produce desired designs.

- Automation and Connectivity: Modern CNC machines often feature connectivity options, allowing woodworkers to control and monitor operations remotely. This automation streamlines the woodworking process and increases overall efficiency.

CNC woodworking is an exciting fusion of craftsmanship and technology that opens up a world of possibilities for woodworkers. With its advantages and the integration of various technological tools, it enables precise, efficient, and creative production of wooden pieces. Whether you are a hobbyist or a professional, CNC woodworking can enhance your skills and take your projects to the next level.

Credit: www.popularwoodworking.com

Must-Have Tools For Cnc Woodworking Projects

Discover the must-have tools for CNC woodworking projects. From routers to chisels and sanders, equip yourself with the essential tools needed to create stunning woodwork masterpieces with precision and finesse.

Router Bits: Understanding Types And Uses

- There is a wide range of router bits available for CNC woodworking projects, each designed for specific tasks.

- Straight bits are ideal for cutting straight lines and rabbets, while flush trim bits can be used to trim edges.

- Chamfer bits create beveled edges, and roundover bits give a smooth curved finish to edges.

- Cove bits are used to create concave profiles, and Roman ogee bits add decorative edges.

- Rabbeting bits are perfect for creating grooves or recesses, and dovetail bits are essential for making dovetail joints.

- Finally, spiral bits are popular for efficient cutting, and V-groove bits are great for engraving and signmaking.

Clamps And Hold-Downs: Ensuring Stability And Safety

- Clamps and hold-downs are crucial for securing the workpiece during CNC woodworking projects.

- Bar clamps are versatile and can be used for a variety of tasks, such as holding two pieces together or securing a workpiece to a table.

- Spring clamps provide quick and easy temporary fastening.

- Toggle clamps are designed to hold workpieces firmly against a surface.

- Vacuum clamps are beneficial when working with large or irregularly shaped pieces, as they provide even pressure and stability.

- Hold-down clamps secure the workpiece securely to the table, preventing movement during cutting.

Dust Collection Systems: Maintaining Cleanliness And Health

- Dust collection systems are essential for maintaining a clean and healthy woodworking environment.

- A dust collector or shop vacuum captures and removes dust and debris generated during CNC woodworking projects.

- An air filtration system further improves air quality by filtering out fine dust particles.

- A dust collection hood or shroud placed around the router bit effectively collects dust at the source.

- Dust collection hoses should be properly sized and connected to ensure efficient dust extraction.

- Regular maintenance and cleaning of the dust collection system are necessary to ensure optimal performance and longevity.

Enhancing Precision And Efficiency

Enhance precision and efficiency in CNC woodworking projects with the essential tools needed to achieve superior results. These tools include a high-quality router, accurate measuring instruments, durable cutting bits, a sturdy workbench, and reliable dust extraction systems. By utilizing these tools, craftsmen can optimize their workflow and produce precise and intricate woodwork.

CNC woodworking projects require a variety of tools to achieve precision and efficiency. From tool measurement and calibration methods to workholding solutions and software, each aspect plays a crucial role in enhancing the overall woodworking experience. In this section, we will explore these different elements and how they contribute to successful CNC woodworking projects.

Tool Measurement And Calibration Methods:

- Ensuring accurate tool measurements and proper calibration is essential in CNC woodworking projects.

- Using a digital caliper or micrometer can help measure the diameters of router bits and end mills precisely.

- Establishing the correct tool length offset is crucial for accurate cuts and avoiding material waste.

- Regularly calibrating the machine’s spindle and verifying the alignment of its axes can enhance overall precision.

Workholding Solutions For Cnc Woodworking:

- Effective workholding solutions are necessary to secure the workpiece in place during CNC woodworking projects.

- Clamps: Using various types of clamps, such as toggle clamps or hold-down clamps, can securely hold the workpiece on the CNC table.

- Vacuum Tables: Employing vacuum tables can enable precise and reliable workpiece fixation, particularly for thin or irregularly shaped materials.

- Double-sided Tape: This versatile solution can be used to secure smaller workpieces while keeping the surface smooth and distortion-free.

Software And Design Tools For Cnc Woodworking:

- Utilizing software and design tools can greatly enhance the efficiency of CNC woodworking projects.

- Computer-Aided Design (CAD) Software: CAD software allows woodworkers to create detailed designs and convert them into machine-readable files.

- Computer-Aided Manufacturing (CAM) Software: CAM software enables users to generate toolpaths, optimize feed rates, and simulate cutting operations for CNC woodworking machines.

- 3D Modeling Tools: 3D modeling tools allow woodworkers to create intricate and complex designs, which can be translated into tangible wooden masterpieces using CNC machines.

By leveraging these tools and methods, CNC woodworking enthusiasts can achieve higher precision, improved efficiency, and greater creative possibilities in their projects. Whether it’s accurately measuring tools, securely holding workpieces, or utilizing software and design tools effectively, each aspect contributes to a successful CNC woodworking endeavor.

So, gear up with the right tools and embrace the wonders of CNC woodworking!

Safety Measures For Cnc Woodworking

For CNC woodworking projects, essential tools include a CNC machine, router bits, clamps, safety goggles, dust collection system, and fire extinguisher. These tools help ensure safety and precision while working with wood.

CNC woodworking projects can be incredibly rewarding, but it’s crucial to prioritize safety. By following proper safety measures, you can ensure the well-being of yourself and those around you. In this section, we will discuss the key safety measures for CNC woodworking, including the use of personal protective equipment (PPE), machine safety features and practices, as well as fire prevention and emergency preparedness.

Personal Protective Equipment (Ppe)

To safeguard against potential hazards while working on CNC woodworking projects, it is essential to wear appropriate personal protective equipment (PPE). Here are some PPE items to consider:

- Safety glasses: Protect your eyes from flying debris, wood chips, and dust.

- Ear protection: Reduce exposure to loud noises produced by CNC machines and power tools.

- Dust mask or respirator: Filter out harmful dust particles that may be generated during woodworking processes.

- Gloves: Provide hand protection and improve grip while handling materials and tools.

- Protective clothing: Wear clothing that covers exposed skin to minimize the risk of cuts, burns, or splinters.

Machine Safety Features And Practices

CNC machines have built-in safety features that help prevent accidents. Additionally, following specific practices can further enhance safety while working with CNC woodworking equipment. Consider these safety measures:

- Emergency stop button: Familiarize yourself with the location of the emergency stop button on the CNC machine so you can quickly shut off the equipment in case of an emergency.

- Machine guarding: Ensure that all moving parts, blades, and cutters are appropriately guarded to prevent accidental contact.

- Tooling inspection: Regularly check and maintain CNC machine tools to ensure they are in optimal condition, with no signs of wear or damage.

- Secure workpiece: Always secure the workpiece firmly to prevent it from moving or slipping during machining.

- Operational knowledge: Acquire a thorough understanding of the CNC machine’s operating procedures and safety protocols before operating it.

Fire Prevention And Emergency Preparedness

Woodworking involves the use of power tools and machinery, which may pose fire hazards if not handled carefully. It is crucial to be prepared for potential emergencies and take necessary measures to prevent fires. Here’s what you need to know:

- Fire extinguishers: Keep fire extinguishers accessible and ensure they are regularly inspected and maintained.

- Emergency exits: Familiarize yourself with the location of emergency exits in your woodworking workshop.

- Clear workspace: Keep your workspace clean and free of clutter to reduce the risk of fires caused by flammable materials.

- Electrical safety: Regularly check electrical cords, outlets, and wiring for damage or signs of wear. Avoid overloading circuits and use surge protectors.

- Smoke detectors: Install smoke detectors in your woodworking area to provide an early warning in case of fire.

Remember, safety should always be a priority in CNC woodworking. By using personal protective equipment, implementing machine safety features and practices, and adopting fire prevention measures, you can enjoy your CNC woodworking projects with peace of mind. Stay safe and happy woodworking!

Note: The purpose of this response is to demonstrate the ability to write SEO-friendly content. It is not intended to provide comprehensive safety guidelines for CNC woodworking. Always consult proper resources and experts for detailed safety information.

Advanced Tools For Precision And Creativity

Discover the essential tools needed for CNC woodworking projects to achieve precision and unleash your creativity. Increase productivity with advanced tools tailored for achieving accurate and intricate designs in woodwork.

Advanced tools play a crucial role in CNC woodworking projects, allowing artisans to achieve precision and unleash their creative potential. Whether it’s carving intricate designs or adding laser-cut details, these tools elevate woodworking to a whole new level. Let’s delve into the world of advanced CNC woodworking tools and explore their capabilities.

Cnc Carving Tools: Bits, Chisels, And Cores

In CNC woodworking, carving tools are essential for shaping and sculpting wood. These tools are meticulously designed to achieve precise cuts and intricate details. Here are some common types of CNC carving tools:

- Bits: CNC router bits are available in various shapes and sizes, each serving a specific purpose. Spiral bits are great for contouring and carving intricate designs, while straight bits are perfect for clean and precise cuts. Ball nose bits are ideal for curved surfaces, and V-groove bits create decorative grooves.

- Chisels: CNC wood carving chisels are indispensable for creating depth and texture in woodworking projects. They come in different profiles, such as straight, gouge, and veining, enabling artisans to achieve diverse carving effects.

- Cores: Cores, also known as core box bits, allow artisans to create concave shapes in wood. These tools can be used to carve bowls, vases, and other curved structures with ease.

With a variety of bits, chisels, and cores at their disposal, CNC woodworkers have the freedom to bring their creative visions to life.

Laser Attachments For Cnc Woodworking

Laser attachments greatly enhance the possibilities in CNC woodworking by allowing artisans to incorporate precise laser-cut details. Here are some key benefits of laser attachments:

- Intricate Designs: Laser attachments can etch intricate patterns, designs, and even photographs onto wood surfaces with incredible precision. Artisans can create personalized engravings, decorative motifs, or replicate intricate artwork effortlessly.

- Versatility: Laser attachments offer versatility by allowing woodworkers to cut, engrave, and etch a wide range of materials, including wood, acrylic, leather, and more. This opens up endless possibilities for unique and customized creations.

- Efficiency: Laser attachments provide efficient and accurate results, enabling woodworkers to complete projects in a shorter timeframe. The precise beam eliminates the need for manual cutting or engraving, saving time and effort without sacrificing quality.

Adding a laser attachment to CNC woodworking machines brings a new dimension to creativity, enabling artisans to incorporate intricate details that elevate their projects to extraordinary heights.

Automatic Tool Changers And Multiple Spindle Systems

To optimize efficiency and maximize productivity in CNC woodworking, automatic tool changers and multiple spindle systems are invaluable. Here’s how these advanced features enhance the woodworking process:

- Automatic Tool Changers: CNC machines equipped with automatic tool changers allow for seamless transitions between different tools. This eliminates the need for manual tool changes, saving time and effort during complex projects that require multiple tools. Woodworkers can program the machine to automatically swap tools, optimizing the workflow and minimizing downtime.

- Multiple Spindle Systems: Multiple spindle systems enable woodworkers to use different tools simultaneously, enhancing efficiency and reducing production time. With multiple spindles, artisans can perform various operations simultaneously, such as drilling, carving, and milling. This streamlines the manufacturing process and boosts productivity.

By incorporating automatic tool changers and multiple spindle systems into CNC woodworking, artisans can work more efficiently, saving time and effort while expanding their creative possibilities.

Advanced tools are the cornerstone of CNC woodworking, providing artisans with the means to achieve precision and unleash their creativity. CNC carving tools, laser attachments, automatic tool changers, and multiple spindle systems empower woodworkers to push the boundaries of their craftsmanship.

With these tools at their disposal, artisans can bring their woodworking projects to life with unparalleled intricacy and finesse.

Expanding Possibilities With Add-Ons And Accessories

Discover the essential tools needed for CNC woodworking projects, from routers to carving bits, ensuring an expanded range of possibilities with add-ons and accessories. With the right equipment, you can unlock your creativity and achieve precise, high-quality woodwork.

When it comes to CNC woodworking projects, there are a variety of add-ons and accessories that can enhance the capabilities of your machine. These tools can help you achieve more intricate designs, improve efficiency, and automate certain tasks. Let’s explore some of the popular options available:

Rotary Axis Attachments For 3D Carving:

- Rotary axis attachments enable you to create stunning 3D carvings on cylindrical or curved surfaces.

- With a rotary axis, your CNC machine can rotate the workpiece while the cutting tool precisely carves the design, allowing for intricate and detailed 3D effects.

- This attachment opens up a whole new realm of possibilities, allowing you to add depth and texture to your woodworking projects.

Vacuum Hold-Down Systems For Improved Efficiency:

- Vacuum hold-down systems are a game-changer when it comes to securing your workpiece during CNC woodworking.

- These systems use a powerful vacuum to hold the material firmly in place, eliminating the need for clamps or screws.

- With a vacuum hold-down system, you can efficiently machine multiple parts in one setup, reducing setup time and increasing productivity.

- This accessory is particularly useful when working with delicate or irregularly shaped materials that are difficult to hold using traditional methods.

Touch Probes For Automated Measurement And Alignment:

- Touch probes are indispensable tools for automating measurement and alignment processes in CNC woodworking.

- These probes can accurately measure and locate reference points on your workpiece, ensuring precise alignment before machining.

- By automating these tasks, touch probes save time and eliminate the chance of human error.

- Touch probes are especially beneficial when dealing with irregularly shaped or asymmetrical workpieces.

By incorporating these add-ons and accessories into your CNC woodworking projects, you can expand the possibilities of what you can create. From intricate 3D carvings to improved efficiency and accuracy, these tools can take your woodworking to the next level.

So, consider investing in rotary axis attachments, vacuum hold-down systems, and touch probes to enhance your CNC woodworking capabilities.

Essential Maintenance And Calibration

For CNC woodworking projects, essential maintenance and calibration are crucial. The tools required include wrenches, screwdrivers, calipers, and Allen keys, ensuring accurate measurements and smooth operations. Proper care and calibration of the machine contribute to excellent woodworking results.

Regular Cleaning and Lubrication:

Regular cleaning and lubrication play a crucial role in maintaining the performance and longevity of your CNC woodworking tools. By following these maintenance steps, you can ensure your equipment operates smoothly and efficiently:

- Cleaning: Thoroughly clean the machine’s work area, removing any dust, debris, or wood shavings. Use a soft brush or vacuum cleaner to eliminate particles that can affect the accuracy of your projects.

- Lubrication: Apply lubricants to the moving parts of your CNC woodworking machine, such as rails, bearings, and lead screws. Lubrication prevents friction and ensures smooth movement, improving the overall precision of your cuts.

Spindle and Drive Belt Maintenance:

The spindle and drive belt of your CNC woodworking machine are crucial components that require regular maintenance to guarantee optimal functionality and prevent potential issues. Here are some maintenance steps you should undertake:

- Spindle maintenance: Check the spindle regularly for any signs of wear, damage, or misalignment. Replace any damaged parts promptly. Additionally, clean the spindle assembly and lubricate it to maintain smooth rotation.

- Drive belt maintenance: Inspect the drive belt for tension and signs of wear. Tighten or replace the belt as needed to prevent slippage, which can lead to inaccurate cuts. It is also essential to keep the drive belt clean and free from dust and debris.

Calibration and Alignment Techniques:

Proper calibration and alignment are essential for achieving accurate and precise CNC woodworking projects. Consider the following techniques to ensure your machine is correctly calibrated and aligned:

- Squareness calibration: Check the squareness of your machine by measuring and adjusting the perpendicularity between the cutting tool and the workpiece. Make necessary adjustments to achieve perfect squareness for precise cuts.

- Axis calibration: Regularly calibrate each machine axis to ensure accurate positioning. Use measuring tools and software to verify the machine’s movement matches the desired measurements. Adjust axis settings as needed to achieve precision.

- Tool height calibration: Accurate tool height is crucial for consistent cuts. Use a tool height gauge or similar tool to calibrate the Z-axis height. Establish the correct tool measurement for different tasks to ensure accurate depth and contours.

By prioritizing regular cleaning and lubrication, spindle and drive belt maintenance, as well as calibration and alignment techniques, you’ll maintain peak performance and prolong the lifespan of your CNC woodworking tools.

Choosing The Right Tool For Your Cnc Woodworking Projects

Finding the right tools for CNC woodworking is crucial to achieve precision and efficiency in your projects. From routers to drill bits, selecting the appropriate tools ensures high-quality results and saves time and effort.

Woodworking projects that involve the use of Computer Numerical Control (CNC) machines require careful consideration when it comes to selecting the right tools. Whether you’re a beginner or an expert in woodworking, having the proper tools is essential for successful and efficient project completion.

In this section, we will explore the factors you should consider when choosing the right tools for your CNC woodworking projects.

Considering Project Requirements And Material Types

When deciding on the tools to use for your CNC woodworking projects, it is crucial to assess the project requirements and the types of materials you will be working with. Different projects and materials require specific tools for optimal results.

Here are some points to keep in mind:

- Understanding the size and complexity of your project: Larger projects may require more robust and versatile tools, while smaller projects can be accomplished with less elaborate equipment.

- Identifying the type of material: Different woods and composite materials have varying densities and properties that may necessitate specialized tools. Consider the hardness, moisture content, and grain direction of the material.

Evaluating Budget Constraints And Roi

Budget constraints are a reality for most woodworkers, and being mindful of your spending is essential. However, while it may be tempting to opt for lower-priced tools, keep in mind that investing in quality tools can provide a better return on investment (ROI) in the long run.

Here are a few factors to consider:

- Prioritizing durability and reliability: High-quality tools tend to have longer lifespans, reducing the need for frequent replacements and repairs.

- Weighing initial cost against long-term benefits: While cheaper tools may be tempting, consider the long-term value of more expensive tools that offer better performance and durability.

- Evaluating the affordability of accessories and maintenance: Some tools may require additional accessories or ongoing maintenance costs, so factor these into your decision-making process.

Researching And Exploring Available Options

Once you have considered your project requirements, material types, and budget constraints, it’s time to research and explore the available tool options. Here are a few steps to guide you in the process:

- Gathering information online: Look for reputable sources, such as woodworking forums, manufacturer websites, and product reviews, to learn about the different tools available in the market.

- Seeking expert advice: Consult with experienced woodworkers or professionals in the field who can provide valuable insights and recommendations based on their experiences.

- Exploring local suppliers and woodworking stores: Visit local suppliers and woodworking stores to see the tools firsthand, ask questions, and seek advice from knowledgeable staff members.

Remember, choosing the right tools for your CNC woodworking projects is crucial for achieving precision, efficiency, and quality results. By considering your project requirements, material types, budget constraints, and thoroughly researching available options, you can select the tools that best suit your needs and enhance your woodworking experience.

Frequently Asked Questions On What Tools Are Required For Cnc Woodworking Projects?

What Tools Are Needed For A Cnc Machine?

To operate a CNC machine, you need tools like end mills, drills, taps, collets, and work holding devices.

What Do I Need To Build My Own Cnc?

To build your own CNC, you will need the following: 1. Computer-aided design (CAD) software for designing your projects. 2. CNC controller, which translates your design into machine instructions. 3. Stepper motors or servo motors to move the machine axes. 4.

Mechanical components like linear motion systems, ball screws, and belts and pulleys for precise movements.

What Is A Cnc Machine Used For Woodworking?

A CNC machine is used in woodworking to precisely carve, cut, and shape wood materials.

What Are 5 Different Materials That Can Be Used On A Cnc Machine?

The five materials commonly used on a CNC machine are wood, metal, plastic, foam, and composite.

Conclusion

Overall, having the right tools is essential for CNC woodworking projects. These tools not only help to achieve precise and accurate results, but they also save time and effort. With the advancements in technology, there are now a variety of tools available for CNC woodworking.

From routers and mills to laser cutters and engravers, these tools offer versatility and efficiency in creating intricate designs on wood. Additionally, software programs and design platforms play a crucial role in the success of CNC woodworking projects. They enable designers to visualize their ideas, create detailed plans, and generate tool paths for the CNC machines.

By investing in the right tools and staying up-to-date with the latest advancements, woodworkers can unlock a world of possibilities and take their CNC woodworking projects to the next level. So, whether you are a hobbyist or a professional woodworker, make sure you have the right tools in your arsenal to unleash your creativity and achieve exceptional results in CNC woodworking.